News Center

social responsibility

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

![]() Release date:2024.11.06

Release date:2024.11.06

![]() Page view:53

Page view:53

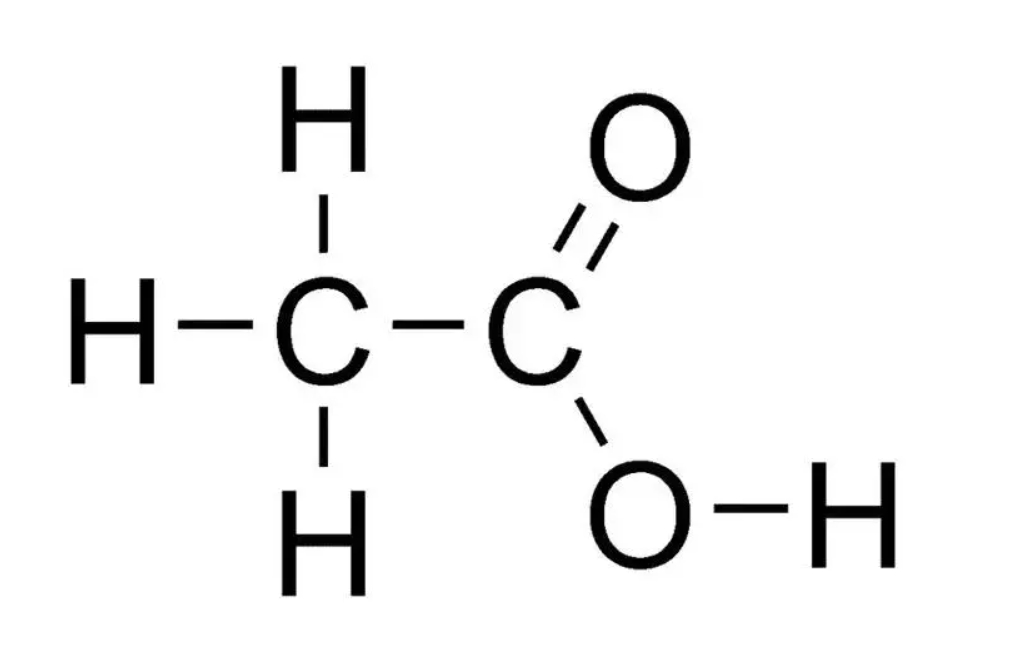

Acetic acid, as a vital chemical basic raw material, is widely used in the production process of solvent preparation and organic synthesis intermediates. However, in its manufacturing process, a large amount of acetic acid wastewater is inevitably generated. In view of the low concentration of acetic acid mass fraction less than 5% in such wastewater, the industry usually uses tributyl phosphate (TBP) as a highly efficient extraction agent to effectively extract acetic acid components from wastewater.

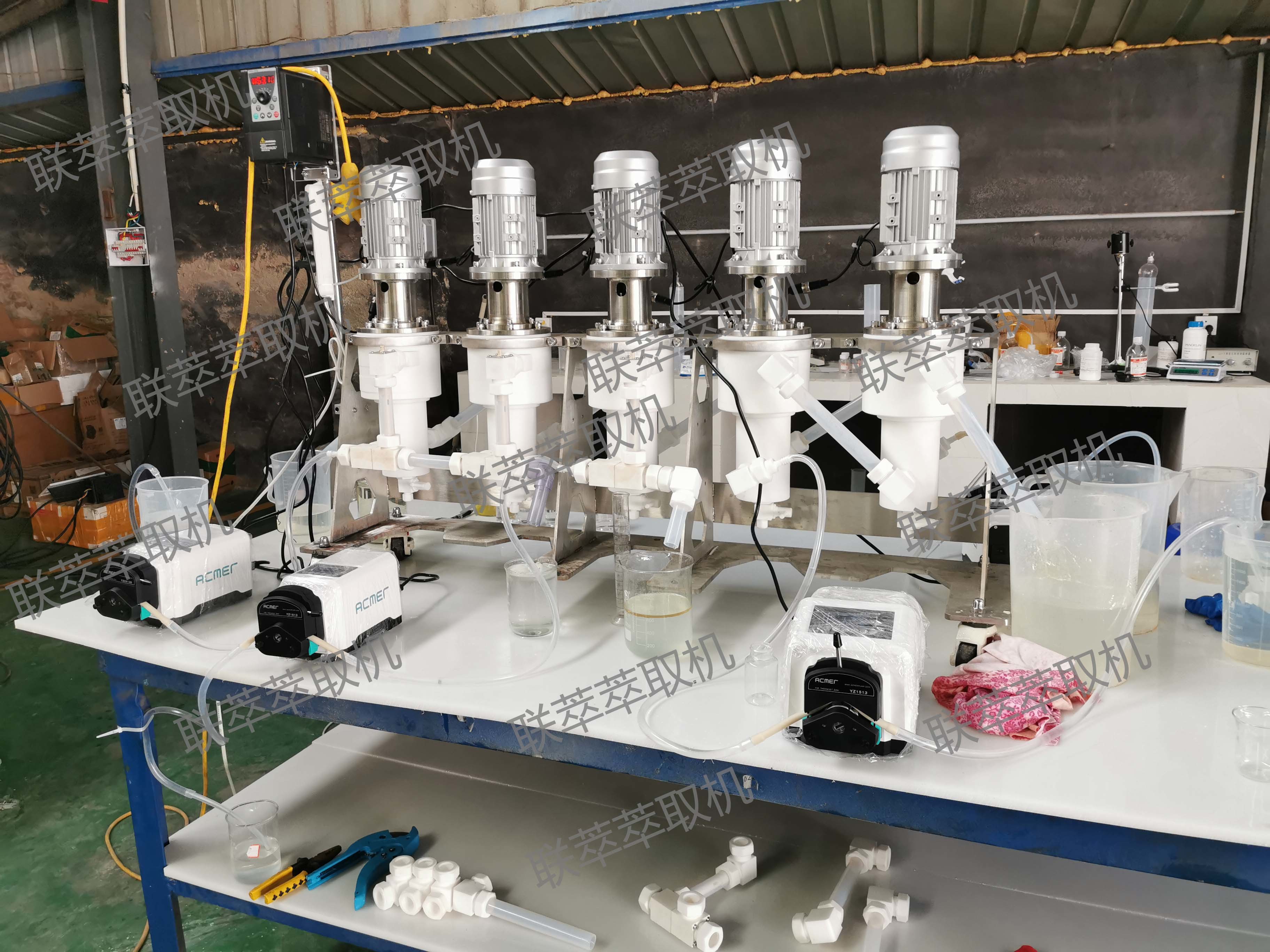

Specifically, we introduced a centrifugal extractor to carry out deep extraction treatment of wastewater with acetic acid mass fraction of about 2.5% through the precision design of a multistage tandem countercurrent system. The practical results show that the extraction efficiency of this system is very high, which can reach more than 97%. It is worth noting that the entire process is carried out in a closed, continuous and highly automated environment, which significantly reduces the consumption of extractant and significantly increases production efficiency. This innovative technology is not only a substantial optimization of the traditional mixing tank static treatment process, but also a major technological leap in the field of wastewater treatment and resource utilization.

Centrifugal solvent extraction technology, as the core technical means of wastewater treatment and resource utilization, has shown great potential in solving the problem of circular ecological pollution. At the same time, this technology is also one of the key paths to promote the goal of carbon neutrality. In fact, the technology has been successfully applied to a variety of wastewater treatment processes, including but not limited to phenol-containing wastewater, sodium naphthalene sulfonate wastewater, DMF wastewater, DMAC wastewater and sebacic acid wastewater, and has achieved significant engineering application results.

Taking the treatment of phenol-containing wastewater as an example, through the comprehensive application of CTX multistage countercurrent centrifugal extraction and reverse extraction technology, the content of phenolic substances in wastewater is effectively reduced to less than 100ppm, and the operation cost of the whole treatment process is very low, and the economic benefits are significant.

In the field of DMAC wastewater treatment, the traditional distillation method with high energy consumption is used. However, through the introduction of the combined extraction-rectification process, we have successfully enriched DMAC into a solvent system with lower specific heat capacity and boiling point, and thus achieved a significant reduction in the energy consumption of the rectification process. Especially in the treatment of DMAC wastewater with a concentration of less than 30% (w/w), compared with direct distillation, the combined extraction-distillation process has an energy saving effect of more than 65%.

The multi-stage countercurrent process of centrifugal extractor has shown excellent performance and broad application prospect in acetic acid wastewater treatment and other wastewater treatment fields.

Previous: Extraction of taxone

Hot spot

Welcome to contact you by phone

Working hours(8:30-20:30)Enquiry hotline

+86 13255260239

Pay attention to customer service wechat

Working hours(8:30-20:30)