News Center

social responsibility

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

![]() Release date:2024.11.11

Release date:2024.11.11

![]() Page view:68

Page view:68

Application of centrifugal extractor in taxone extraction

Taxone, commonly referred to as Paclitaxel (Paclitaxel), is a highly effective anticancer drug derived from a natural component of the taxus family of plants. Because of its unique anti-cancer mechanism, paclitaxel has become an important drug in the treatment of a variety of malignant tumors (such as ovarian cancer, breast cancer and lung cancer). However, the content of paclitaxel in plants is very low, and the extraction process is complex, so efficient and energy-saving extraction technology is particularly important. Centrifugal extractor, as an advanced liquid-liquid extraction equipment, plays an important role in the extraction process of paclitaxel.

Background and challenges of taxol extraction

Paclitaxel does not exist naturally in a free state, but needs to be extracted from plants such as taxus chinensis. Traditional extraction methods include natural extraction, artificial synthesis, semi-artificial synthesis and biological fermentation, but these methods are either inefficient or costly, and many are still in the experimental stage. Therefore, the development of an efficient and low-cost paclitaxel extraction technology has become a research hotspot.

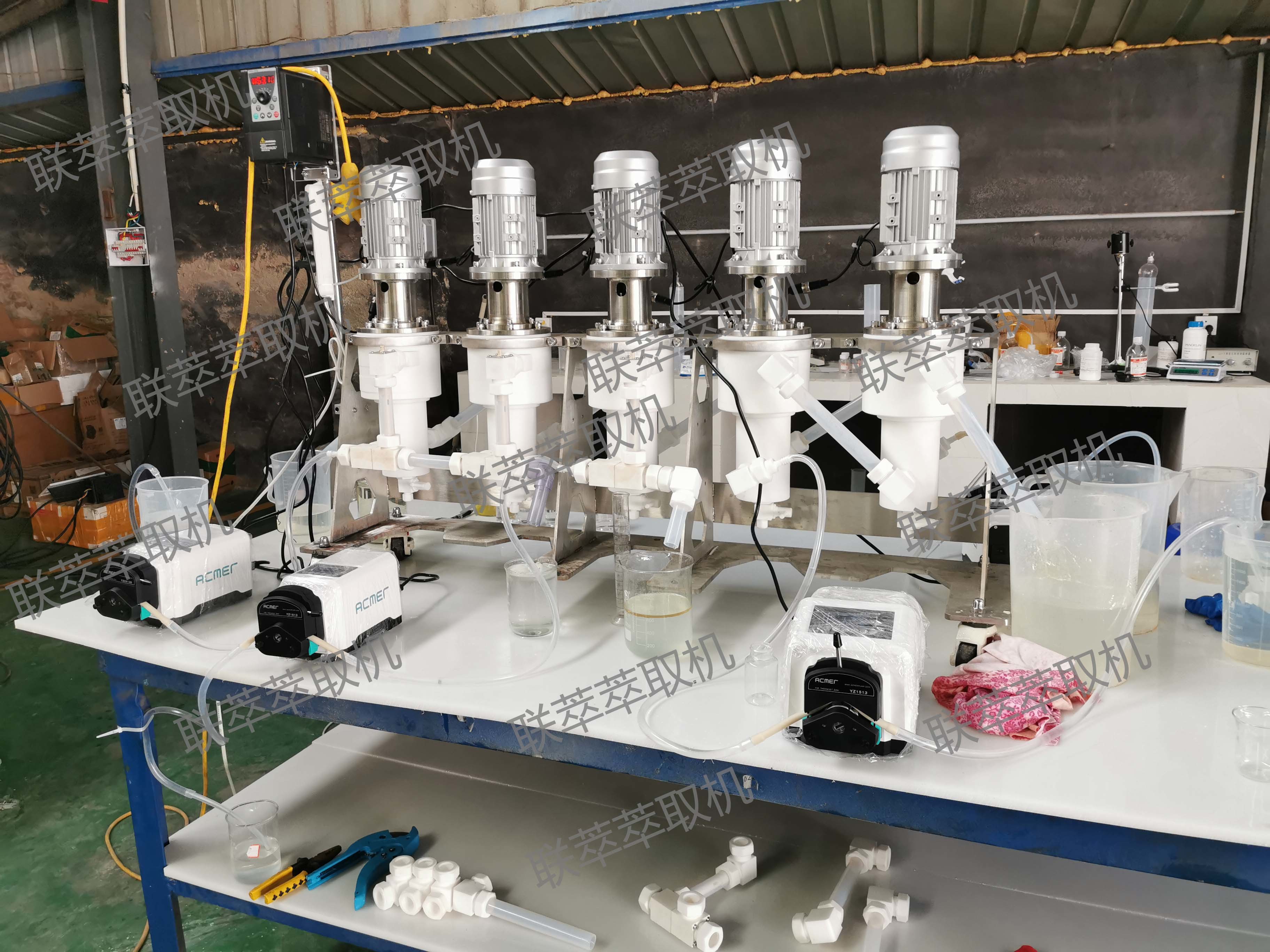

The working principle and advantage of centrifugal extractor

Centrifugal extractor is a kind of equipment which uses centrifugal force to accelerate liquid-liquid separation. It is done by mixing two insoluble liquids (usually plant extracts and organic solvents) in a rotating drum at high speed, so that the solute is fully exchanged between the two phases, and then fast separation is achieved under the action of centrifugal force. Centrifugal extractors have the following significant advantages:

High efficiency extraction: Due to the role of centrifugal force, the two-phase liquid can be fully mixed and dispersed in the drum, which greatly improves the mass transfer efficiency of the solute.

Energy saving: Compared with the traditional stirring extraction method, the centrifugal extractor can significantly reduce solvent consumption and energy waste.

High degree of automation: centrifugal extractors are usually equipped with advanced control systems, which can achieve automated operation, reduce manual intervention, and improve production efficiency.

Environmentally friendly: the centrifugal extractor can achieve closed operation, reduce the emission of harmful substances, and meet the requirements of environmental protection.

Application of centrifugal extractor in paclitaxel extraction

In the extraction process of paclitaxel, the centrifugal extractor usually adopts solvent extraction method. Specific steps include:

Crushing and extraction: After the taxus plant material is broken, it is extracted with an appropriate solvent (such as methanol, ethanol or ethyl acetate, etc.), so that the active ingredients such as paclitaxel are dissolved in the solvent.

PH regulation and extraction: By adjusting the PH value of the extract, the active ingredients such as paclitaxel are free from the water, and then the extraction is carried out with organic solvents.

Centrifugal extraction: The solution containing paclitaxel and the organic solvent are added to the centrifugal extractor for liquid-liquid extraction. Under the action of centrifugal force, the active ingredients such as paclitaxel are extracted into the organic solvent.

Purification and crystallization: The extracted organic solvent is purified, impurities are removed, and high-purity paclitaxel products are obtained through crystallization and other steps.

The centrifugal extractor showed significant advantages of high efficiency, energy saving and high degree of automation in the extraction process of paclitaxel. With the continuous progress of science and technology and the increasing market demand, the application prospect of centrifugal extractors in the field of paclitaxel and other natural products extraction will be broader. In the future, we can look forward to the application of more innovative technologies, such as membrane separation, ultrasonic assisted extraction, etc., combined with centrifugal extractors, to further improve the extraction efficiency and purity of paclitaxel, and provide more powerful support for the research and development and production of anti-cancer drugs.

Hot spot

Welcome to contact you by phone

Working hours(8:30-20:30)Enquiry hotline

+86 13255260239

Pay attention to customer service wechat

Working hours(8:30-20:30)