News Center

social responsibility

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

![]() Release date:2024.10.28

Release date:2024.10.28

![]() Page view:139

Page view:139

The rare earth extraction separation process, as the core technology for the purification and separation of rare earth elements, relies on the significant difference in the distribution ratio of substances in two phases (such as organic phase and water phase) that are not mutually soluble, and achieves accurate separation and high purification of rare earth elements through advanced means such as solvent extraction. In this complex and fine process, the combined extraction centrifugal extractor plays an indispensable role with its unique advantages.

Concentration of mineral processing

As the first key link of the rare earth extraction separation process, mineral processing is used to enrich rare earth elements from the original ore by flotation, gravity separation and magnetic separation, remove a large number of impurities, and provide high-quality rare earth concentrate for subsequent solvent extraction. Taking the rare earth deposit of Bayan Obo Mine in Inner Mongolia as an example, the content of rare earth oxides has been significantly increased after fine mineral processing process, which has laid a solid foundation for subsequent treatment.

Application of solvent extraction and combined extraction centrifugal extractor

Solvent extraction is the core step of rare earth purification and separation, and its efficiency and purity directly affect the quality of the final product. In this process, the combined extraction centrifugal extractor stands out with its high efficiency and environmental protection characteristics, and has become an important force to promote the progress of rare earth extraction technology.

Principle and technology of solvent extraction

Based on the difference of substance distribution ratio between two phases, solvent extraction achieves efficient transfer of rare earth elements by selecting suitable extractant and optimizing extraction conditions. In this process, the application of advanced technologies such as fuzzy extraction separation technology and acidic phosphorus extractants (such as P507 and P204) further improves the accuracy and efficiency of extraction.

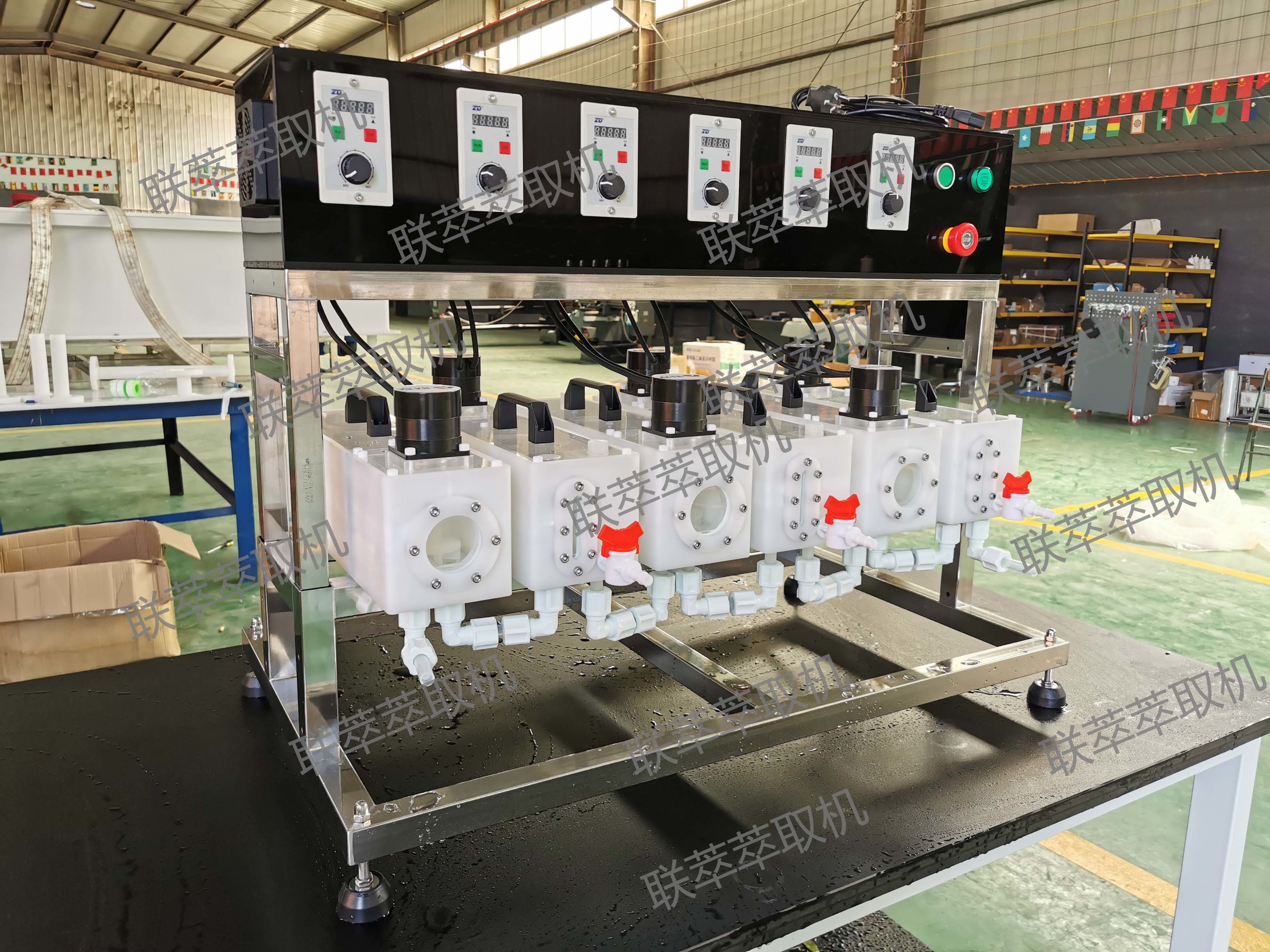

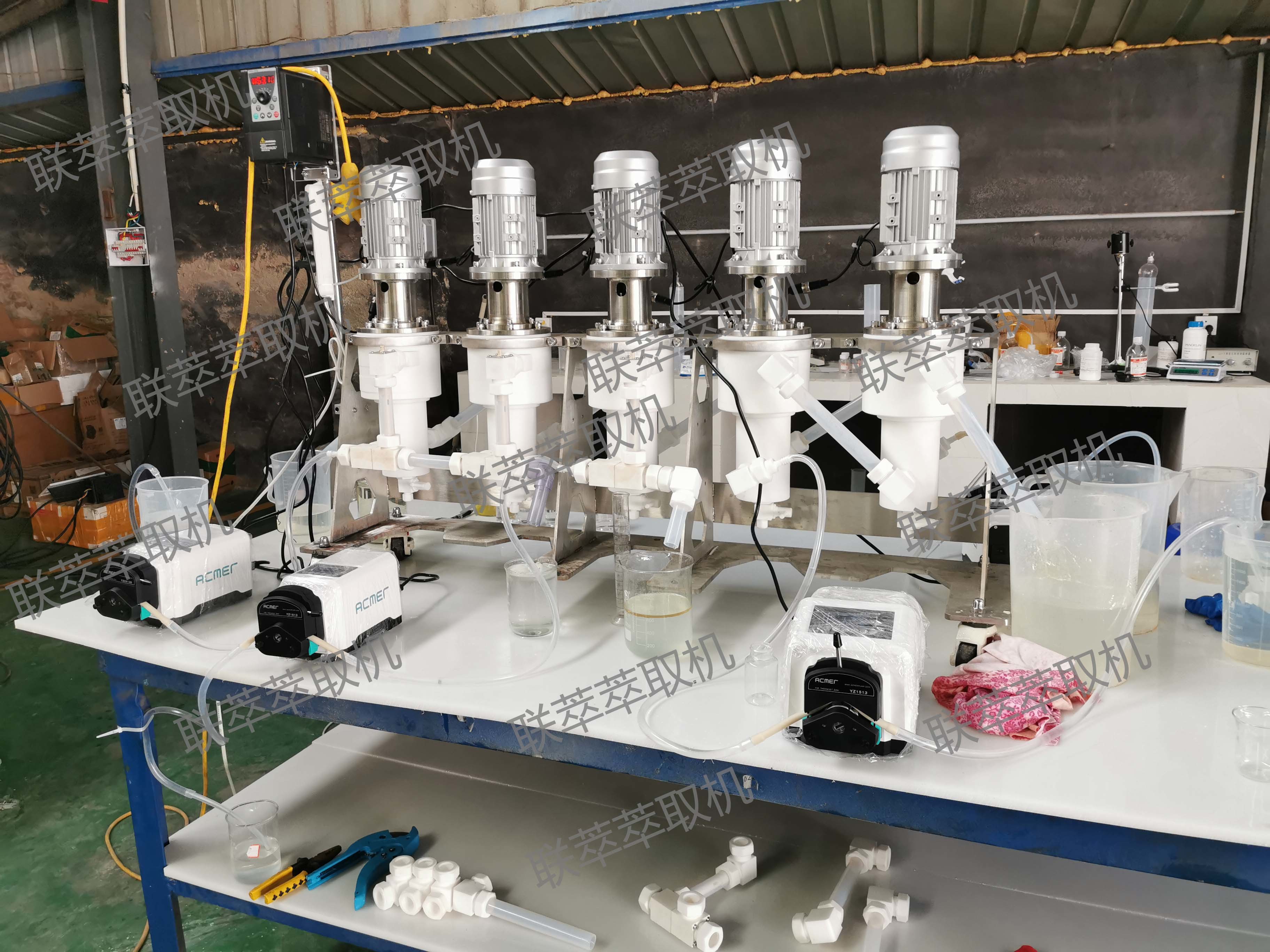

Advantages of combined extraction centrifugal extractor

The combined extraction centrifugal extractor skillfully combines centrifugal separation with solvent extraction, and uses centrifugal force to accelerate the extraction process, which significantly improves the extraction efficiency and processing capacity. Its characteristics are:

Efficient extraction: By enhancing the mass transfer efficiency, shorten the extraction time, and improve the recovery rate of rare earth elements.

Energy saving and environmental protection: reduce the consumption of organic solvents and waste water discharge, in line with the green production concept.

Automation control: Integrated advanced control system to achieve accurate regulation and remote monitoring of the extraction process, reduce manual operation costs, improve production safety.

Solvent extraction process optimization

After the introduction of the combined extraction centrifugal extractor, the solvent extraction process was further optimized. The extraction, washing and back extraction steps are carried out in a more efficient and stable environment, ensuring high purity extraction and separation of rare earth elements. At the same time, the amount of extractant and washing times are reduced, the production cost is reduced, and the overall economic benefit is improved.

The application of combined extraction centrifugal extractor in rare earth extraction separation process not only improves the purification efficiency and purity of rare earth elements, but also promotes the green and efficient development of rare earth industry. With the continuous progress of technology and the continuous expansion of application, the combined extraction centrifugal extractor will play a more important role in the field of rare earth, and contribute to the sustainable utilization of rare earth resources and industrial upgrading.

Hot spot

Welcome to contact you by phone

Working hours(8:30-20:30)Enquiry hotline

+86 13255260239

Pay attention to customer service wechat

Working hours(8:30-20:30)