News Center

social responsibility

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

![]() Release date:2024.10.28

Release date:2024.10.28

![]() Page view:62

Page view:62

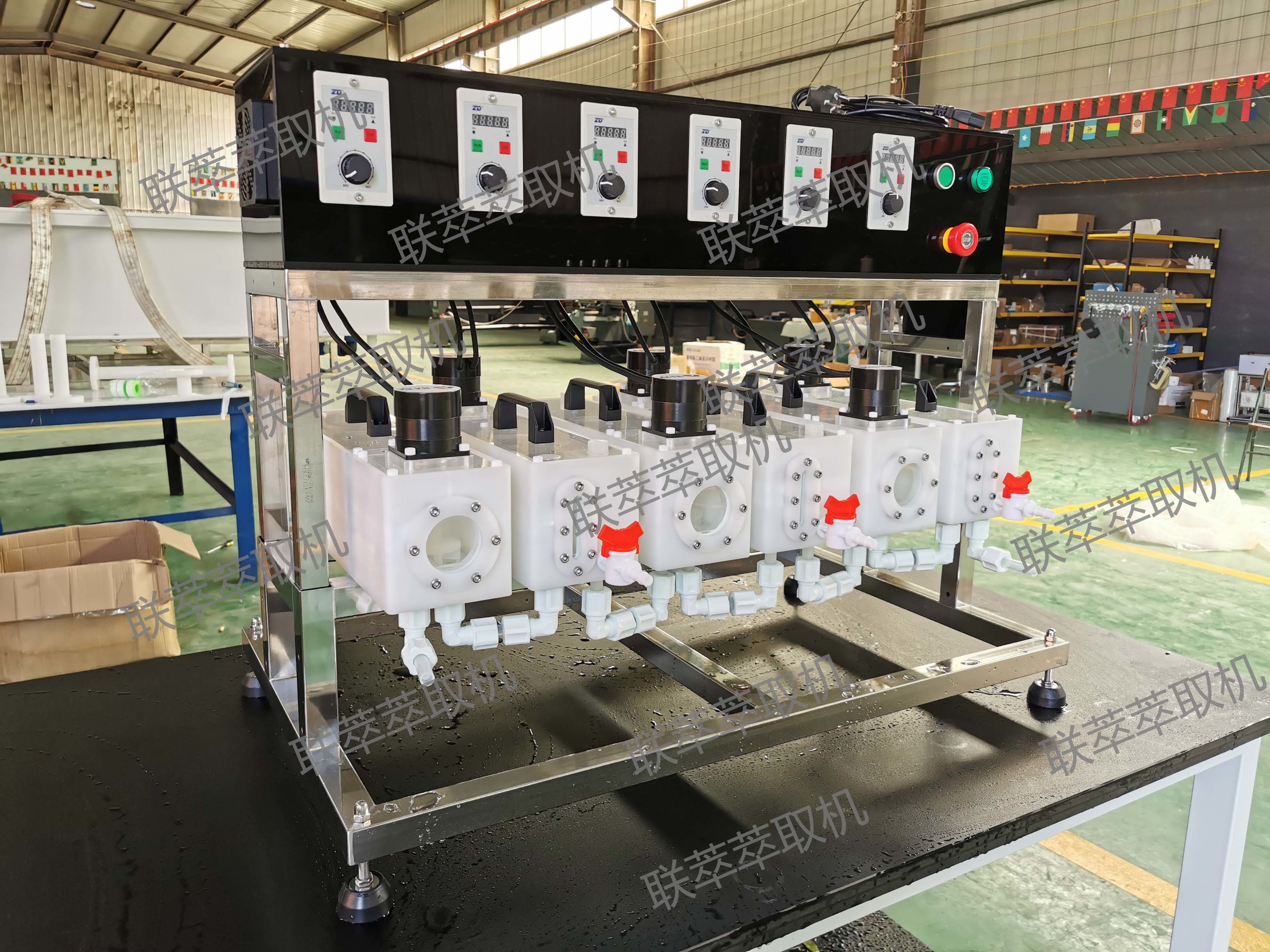

As an important branch of chemical separation technology, the extraction of aldehydes and aqueous phase is mainly based on the difference in solubility of aldehydes in aqueous phase and organic solvent to achieve effective separation through selective dissolution of specific solvents. In this process, the combined extraction centrifugal extractor, with its efficient centrifugal separation technology and excellent mixing uniformity, has become a key equipment to improve extraction efficiency and purity.

Selection and optimization of extractant

In order to ensure the efficient transfer of aldehydes from the aqueous phase to the organic solvent, it is essential to select the right extractant. Organic solvents such as ethers, esters, ketones and dichloromethane (DCM) are often used as extractants because of their good solubility to aldehydes and their inmiscibility with water. However, in specific cases, it may be necessary to explore the use of special extractants that enhance the interaction with aldehydes through their unique chemical properties, such as the presence of functional groups, to improve extraction efficiency.

Advantages of combined extraction centrifugal extractor

High efficiency centrifugal separation: The combined extraction centrifugal extractor uses strong centrifugal force to accelerate the mass transfer process of aldehyde molecules in the two phases, significantly shortening the extraction time and improving the extraction efficiency.

Improved mixing uniformity: The equipment is designed with an optimized mixing zone to ensure a highly uniform mixing of the aldehyde solution and the water phase in the mixing zone, reducing the loss of extraction efficiency due to uneven mixing.

Automatic operation and monitoring: Integrated advanced control system to achieve automatic operation and remote monitoring of the extraction process, reduce manual intervention, improve production safety and stability.

The extraction method is explained in detail

In the liquid-liquid extraction process, the combined extraction centrifugal extractor first mixes a aqueous phase containing aldehydes with a selected organic solvent. Through the high-speed rotation of the equipment, the two phases are fully contacted, and the aldehydes are gradually transferred to the organic phase due to their high solubility in the organic solvent. Then, the organic phase and the water phase are separated rapidly by centrifugal force, and the organic solution rich in aldehydes is obtained. In this process, the extraction effect can be further optimized by precisely controlling the feed speed, flow rate and mixing intensity.

Application field and prospect

In chemical and pharmaceutical industries, aldehydes are important raw materials or intermediates, and their efficient separation and purification is of great significance for improving product quality and reducing production costs. The application of combined extraction centrifugal extractor in aldehyde and water phase extraction not only improves the extraction efficiency and purity, but also promotes the green production and sustainable development of related industries. With the continuous progress of technology and the continuous optimization of equipment, the application prospect of combined extraction centrifugal extractor in the separation of aldehydes and other complex mixtures will be broader.

Hot spot

Welcome to contact you by phone

Working hours(8:30-20:30)Enquiry hotline

+86 13255260239

Pay attention to customer service wechat

Working hours(8:30-20:30)