News Center

social responsibility

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

![]() Release date:2024.10.25

Release date:2024.10.25

![]() Page view:126

Page view:126

Oil-water extraction, also known as solvent extraction or liquid-liquid extraction, is a unit operation to separate a mixture based on differences in solubility of different components in two immiscible or slightly soluble solvents. With this method, the solute can be efficiently transferred from one solvent to another. In the process of oil-water extraction, oil substances are usually used as solutes, water or other solvents are used as extractants, and the effective separation of oil-water mixture is realized through specific extraction equipment and technological conditions.

Preparatory phase

1. Understand the basic characteristics of the material to be treated (such as oily wastewater), including the composition, density, viscosity and solubility of the oil-water mixture. This is the basis for selecting the appropriate extractant and determining the operating conditions.

2. Based on material information, prepare a detailed test plan, clarify the experimental purpose, expected objectives and safety operation specifications, and lay a theoretical foundation for subsequent operations.

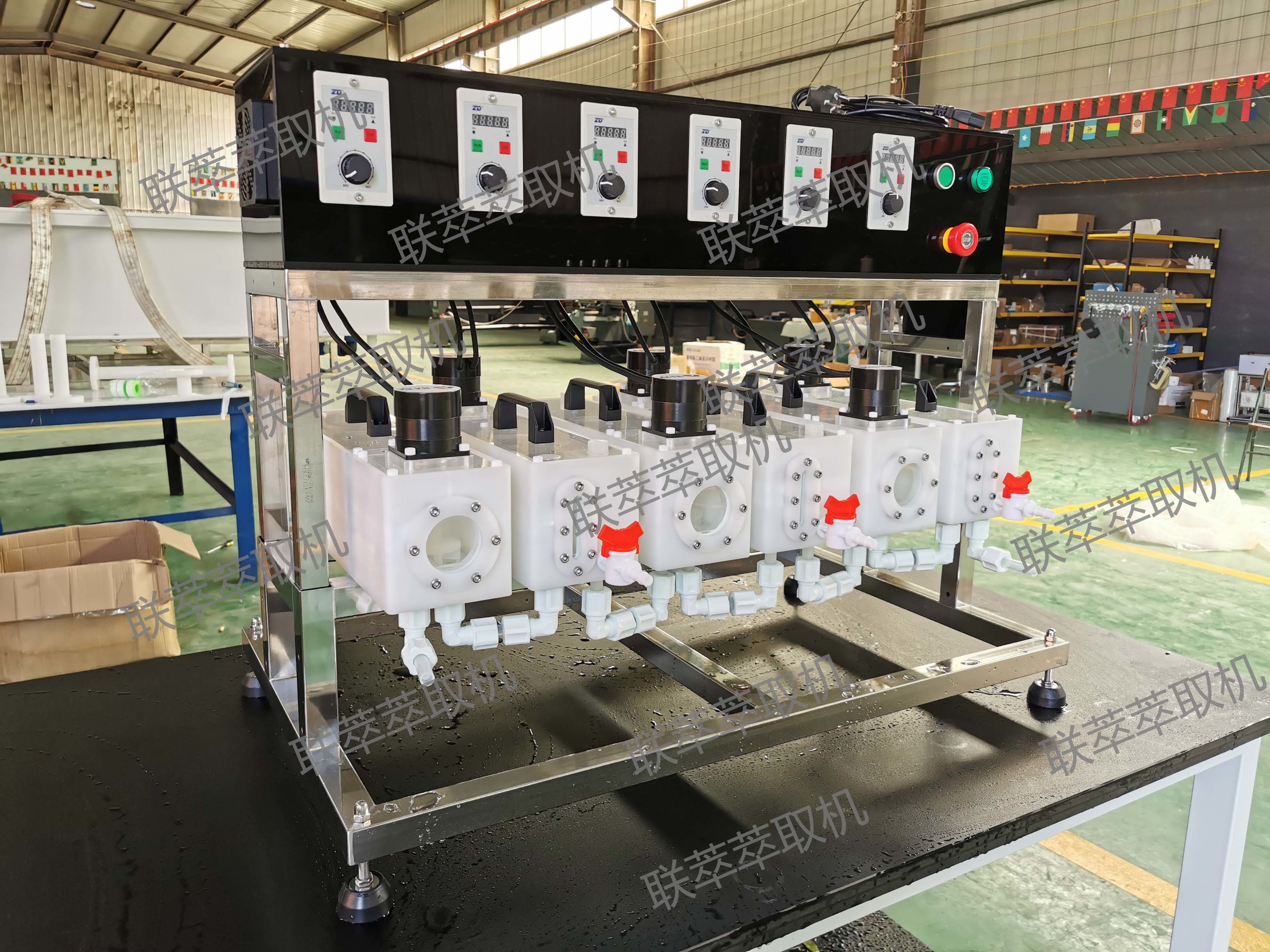

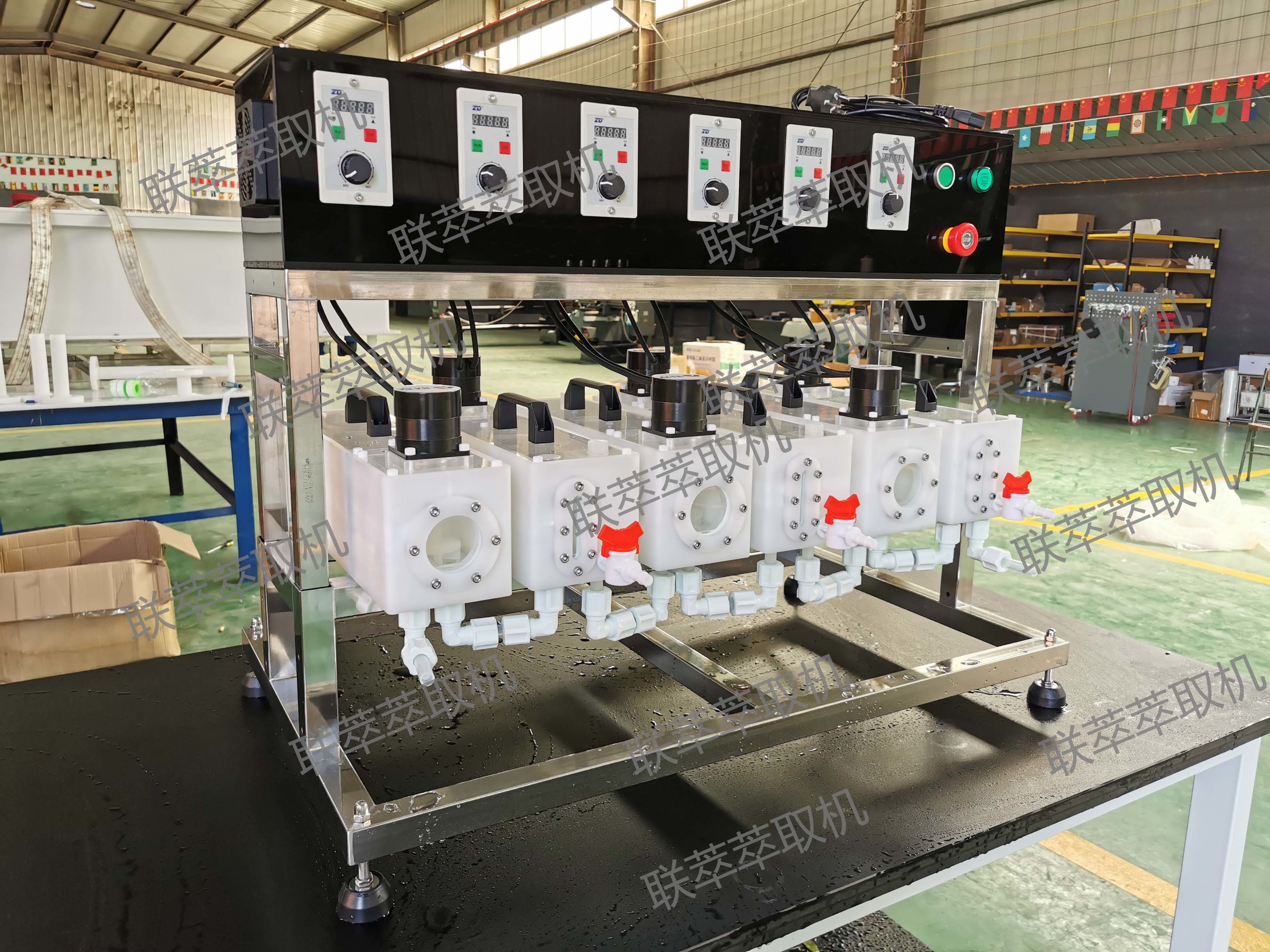

3. Ensure that the centrifugal extractor and auxiliary equipment (such as pumps, storage tanks, etc.) are in good working condition, and prepare sufficient extractant and solvent, while confirming that its quality meets the experimental requirements.

Pretreatment stage

1. : The use of filter screen for preliminary filtration of waste oil to remove impurities such as debris, mechanical waste and carbon particles to obtain preliminary filter oil. This step helps reduce clogging and wear during subsequent processing and increases extraction efficiency.

Centrifugal extraction stage

1. Oil-water separation: Heat the preliminary filtered oil to 50 ~ 70 ° C, and then carry out oil-water separation. The mixture is passed into the oil-water separator to hold heat and settle for 12h ~ 48h, using the density difference, the oil and water are naturally stratified, and the separated oil and separated water are obtained. This step is an important preparation before centrifugal extraction and helps to improve the purity and efficiency of subsequent extraction.

2. Extraction operation

Liquid injection: When the centrifugal extractor reaches a stable working state, the heavy phase liquid (usually water or aqueous solution) is slowly injected first. When the heavy phase outlet has a stable outflow of liquid, then slowly add the light phase liquid (that is, the pre-treated waste oil or extraction agent).

Adjustment parameters: By adjusting the feed rate, centrifuge speed and other parameters, to ensure that the two-phase liquid under the action of centrifugal force can fully contact and effective mass transfer. This process requires close attention to equipment health and separation effects.

Countercurrent extraction: The centrifugal extractor is designed with multiple stages or steps inside to control the flow direction of the liquid through carefully designed flow channels and partitions. The light phase is transferred from the inner layer to the outer layer, while the heavy phase is transferred from the outer layer to the inner layer to realize countercurrent extraction. This countercurrent path helps to increase extraction efficiency and reduce entrainment.

、

Subsequent processing phase

1. Solvent recovery: During the extraction process, part of the extractant may be mixed with the oil to form the extracted oil. In order to recover this part of the extractant and realize recycling, the extracted oil can be added to the aqueous solution for precipitation treatment, and the organic solvent can be recovered through the appropriate separation technology (such as distillation, extraction, etc.).

2. Product treatment: The oil phase and water phase products after centrifugal extraction need to be further treated and purified to meet the requirements of subsequent use. For example, the residual solvents and impurities are removed by distillation, filtration and other methods to improve the purity of the product.

Safety and environmental protection

Throughout the entire process, safety and environmental protection are always the primary considerations. We must strictly abide by the safe operation procedures and environmental requirements to ensure the safety of operators and the sustainable development of the environment. In addition, waste needs to be properly disposed of to prevent pollution to the environment.

Centrifugal oil water extraction process includes preparation stage, pretreatment stage, centrifugal extraction stage, follow-up treatment stage and safety and environmental protection. These steps are linked together to form a complete extraction system that can efficiently separate and purify oil-water mixtures.

Hot spot

Welcome to contact you by phone

Working hours(8:30-20:30)Enquiry hotline

+86 13255260239

Pay attention to customer service wechat

Working hours(8:30-20:30)