News Center

social responsibility

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

![]() Release date:2024.09.24

Release date:2024.09.24

![]() Page view:38

Page view:38

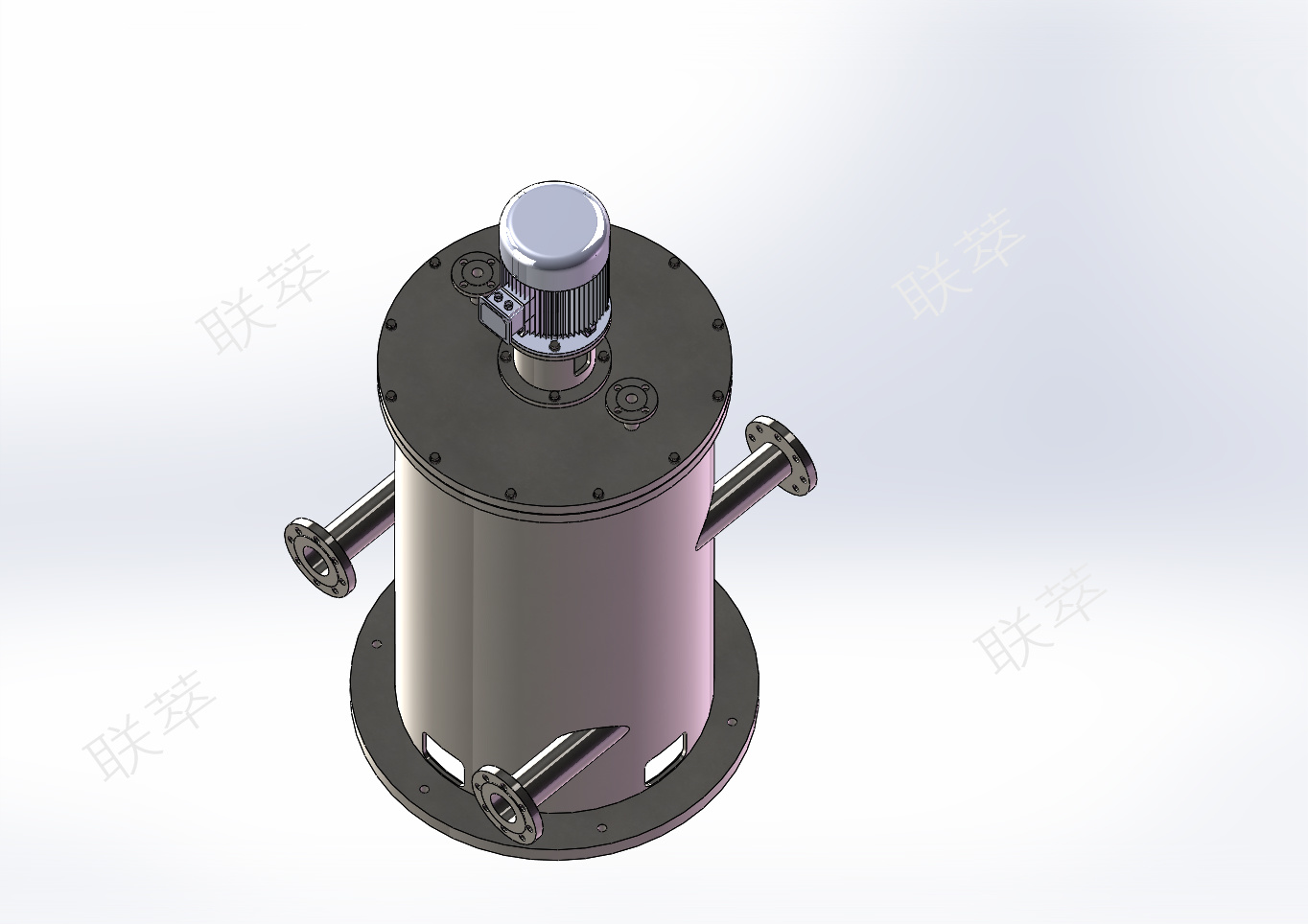

** Cylindrical centrifugal extractor development history at home and abroad **

Solvent extraction is a commonly used separation method, that is, an immiscible organic solvent is added to a solution containing two or more substances, and the difference in the distribution capacity of the substance in the two-phase liquid is used for separation. The existing extraction equipment has various forms, which can be divided into gravity type and centrifugal type according to different forces. Among them, the centrifugal extractor has the advantages of large processing capacity, short two-phase contact time and strong adaptability due to the use of centrifugal force, which makes it occupy a place in industrial applications.

** Foreign development history **

The cylindrical centrifugal extractor can meet the needs of the extraction industry because of its simple structure, high extraction efficiency and large processing capacity. Foreign countries began to study centrifugal extractors in the 1930s, and developed prototypes in the 1940s. By the 1960s, the cylindrical centrifugal extractor was first applied in the reprocessing project of irradiated nuclear fuel in the United States. In the 1970s, such equipment was further perfected and improved, and France applied it to other industrial fields.

At present, there are mainly Argonne Laboratory in the United States and Rousselet Robatel in France in the production of centrifugal extractors. The United States Argonne laboratory mainly produces annular gap high efficiency centrifugal extractor, its products have higher technical parameters, more stable operation, especially suitable for difficult to separate the material system. Rousselet Robatel, a French company, mainly produces stirring wheel type centrifugal extractor. Its stainless steel material is BXP800, drum diameter is 800mm, speed is 970r/min, and the maximum processing capacity is 80m³/h. The maximum type of perfluorinated material is BXP620P, the drum diameter is 620mm, the speed is 580r/min, and the maximum processing capacity is 60m³/h. The equipment is widely used in pharmaceutical, chemical, food, hydrometallurgy, fine chemical and other fields.

Hot spot

Welcome to contact you by phone

Working hours(8:30-20:30)Enquiry hotline

+86 13255260239

Pay attention to customer service wechat

Working hours(8:30-20:30)