News Center

social responsibility

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

![]() Release date:2024.09.13

Release date:2024.09.13

![]() Page view:114

Page view:114

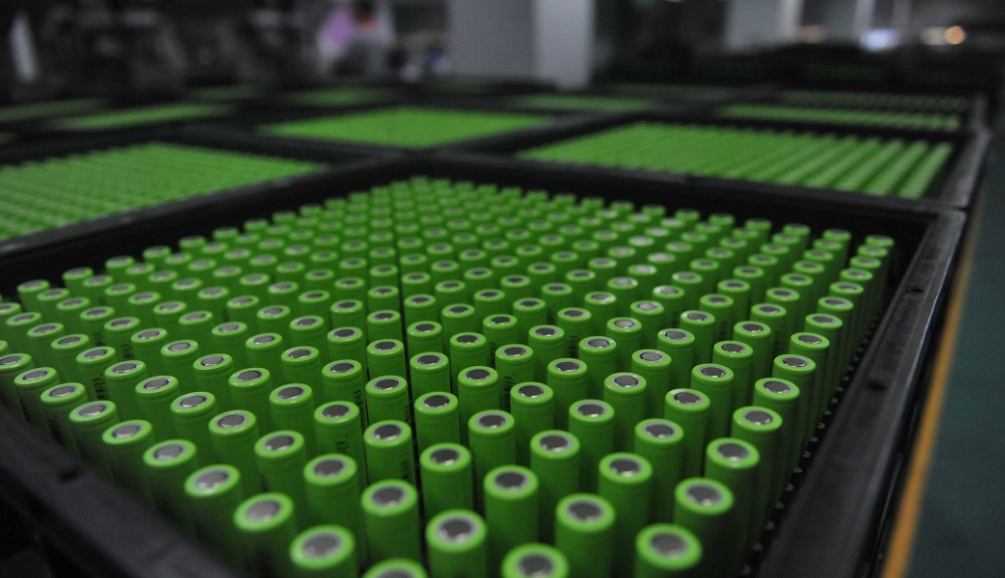

In recent years, with the wide application of lithium-ion power batteries in the passenger car market and the field of energy storage, high energy density and especially high safety performance have become the key criteria for car companies to choose battery suppliers. Studies have shown that metallic foreign bodies (such as iron, zinc, chromium, copper and other elements) in the cathode materials of lithium-ion batteries may penetrate the diaphragm during cold extrusion, leading to mechanical short circuit, or be oxidized into metal ions during charging, migrate to the negative electrode of the battery and form dendrites, and eventually lead to the rupture of the diaphragm leading to chemical short circuit. It causes problems such as battery capacity attenuation, self-discharge rate increase, heating and even fire explosion.

The quality of lithium battery materials, especially the control level of metal and magnetic foreign bodies, is the key to the safety of lithium batteries. The control level of metal and magnetic foreign bodies has also become one of the core indicators to measure the quality of lithium battery material production equipment. The filter washing machine produced by Shandong Liancui Company is widely used in the filter washing section of the lithium battery precursor. The equipment can control the copper and zinc content below 0.5%, and other foreign bodies below 1%, and strictly control the existence of metal and magnetic foreign bodies from the source.

To this end, Shandong Liandui draws on the 5M1E management method and adopts the following measures in six dimensions of human, machine, material, method, environment and measurement:

1. Through optimization design, the parts in contact with materials are planned and improved from the design stage, and the failure mechanism of metal foreign bodies is analyzed. For the parts that are not in contact with the material, the classification design is carried out from the perspective of reducing the cost on the premise of not introducing metal foreign bodies.

2. In strict accordance with user requirements, 316L stainless steel or surface spray PTFE, ECTFE, WC, ceramic powder and other materials. For 304, 316L and other stainless steel materials, we purchase from domestic first-line suppliers such as TISCO and Baosteel, and reinspect; For spraying PTFE, ECTFE materials, we try to choose imported high-quality materials, and test.

3. For purchased parts such as electromagnetic valve bodies, gas pipe joints, ball valves and bearings, we choose first-line brands, and have strict requirements for copper and zinc foreign bodies, and provide material certification documents and test reports.

4. In the manufacturing process, in addition to paying attention to the processing accuracy and assembly quality, we should also focus on the burrs in the material cutting process, the welding slag of the welding parts, and the roughness and surface defect treatment of the contact surface with the material, as well as the details of the round hole chamfering, threaded holes and weld surfaces.

5. Conduct special training for processing personnel to establish quality control awareness of lithium material production equipment. During the welding process, wear soft-soled shoes, do not carry metal items, wrap the torch line with a cloth, and handle gently. During the assembly process, attention should be paid to protecting the processing surface and contact surface, paying attention to the site environment, and paying attention to cleaning up the metal residue worn in the assembly.

6. The quality inspector shall strictly control the process inspection and record, draw the metal map of the equipment after the final inspection, and provide data and document support for material traceability.

7. Maintain a clean and orderly assembly environment to ensure air circulation and clean.

Through the above management measures, we effectively control the presence of metal and magnetic foreign bodies in the equipment. In addition, the filter washer also integrates vacuum feeding, automatic opening and closing of the filter disc and high-precision filter media technologies to support intelligent lithium battery material production.

Hot spot

Welcome to contact you by phone

Working hours(8:30-20:30)Enquiry hotline

+86 13255260239

Pay attention to customer service wechat

Working hours(8:30-20:30)