News Center

social responsibility

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

![]() Release date:2024.09.13

Release date:2024.09.13

![]() Page view:80

Page view:80

As the basic component of electronic products, the printed circuit board (PCB) industry occupies an important position in China's electronics industry, and has developed rapidly in recent years, and the output value has exceeded 100 billion. In the etching process, the quality of the etching fluid is crucial to the quality of the PCB. At present, there are many kinds of etching fluids, among which alkaline copper chloride and acidic copper chloride etching fluids are the most common. These waste etching fluids contain a high amount of copper, but also mixed with ammonia, ammonium chloride, sodium chloride, hydrochloric acid, nitric acid and other components, belong to hazardous waste.

If discharged directly without treatment, it will cause serious pollution to the environment. China's daily production of copper containing waste etching liquid up to thousands of cubic meters, according to 150 kilograms of copper per cubic meter calculation, copper content of more than 500 tons, belongs to the precious secondary resources, its recycling not only significant economic benefits, but also effectively reduce environmental pollution. The methods for treating copper-containing waste etching fluid include neutralization precipitation, replacement, electrolysis and solvent extraction. Among them, the first three methods have the problems of low recovery rate, secondary pollution and high investment.

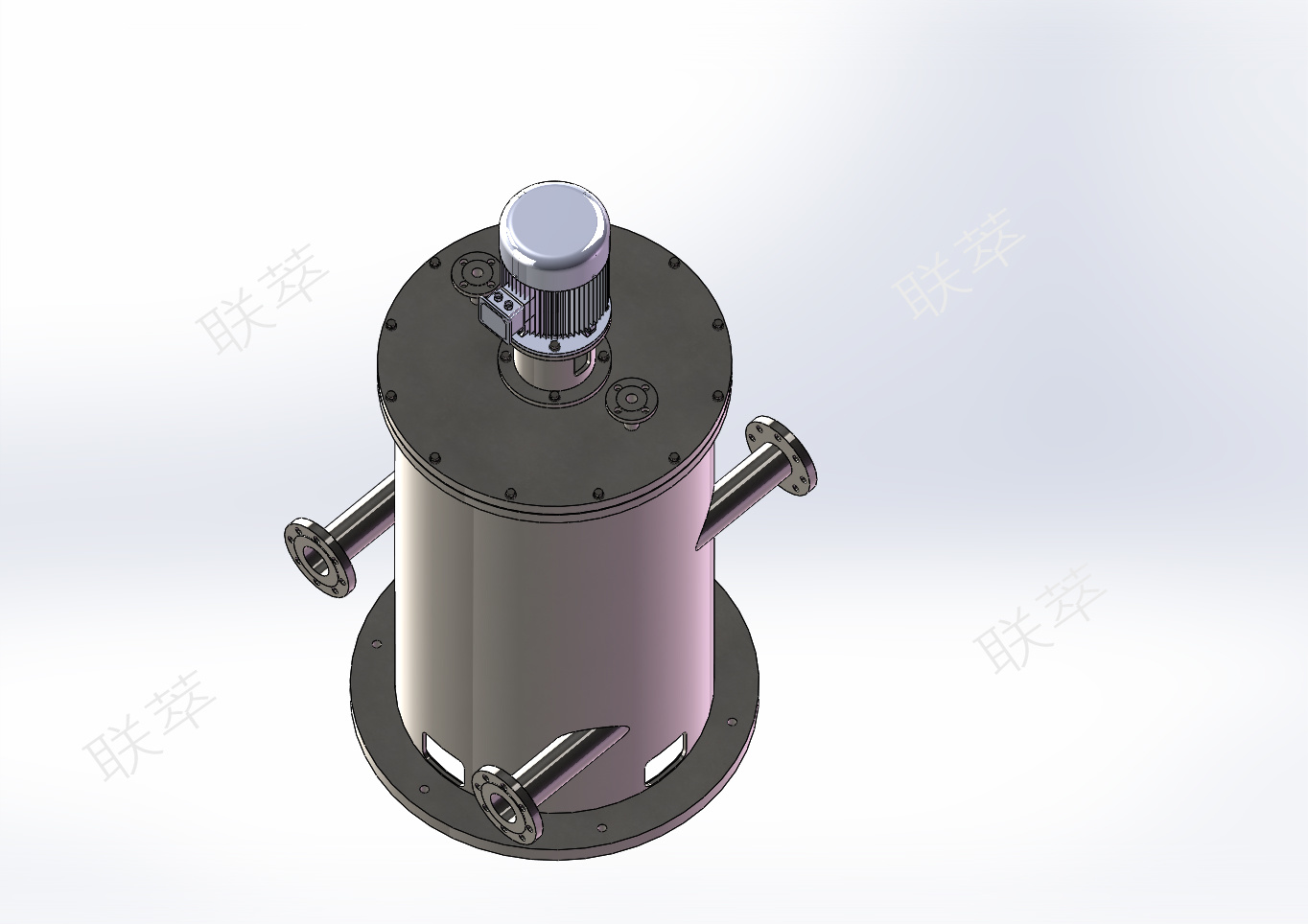

The centrifugal solvent extraction method is used to extract copper ions from the waste etching solution by using an extractant with high solubility to copper ions. The remaining liquid after extraction can be used as the etching liquid again after the composition adjustment. This method has the advantages of high extraction efficiency, green energy saving and low operating cost.

Due to the wide range of pH value of copper-containing waste etching solution and the need to use a variety of extractants, the centrifugal extractor, as the core equipment of solvent extraction method, must have corrosion resistance, high technical parameters and strong adaptability. The CTX high efficiency centrifugal extractor of Hefei General Environment Company uses perfluorinated material or sprayed fluorine material to make the contact part with the material, and has excellent corrosion resistance. The ratio of rotor length to diameter is large, the separation area is long, the mixed mass transfer strength is high, and the extraction efficiency is remarkable. In addition, by optimizing the flow path design, the operating power can be greatly reduced and the operating cost can be saved.

With the appropriate extractant and reasonable allocation, the extraction rate of copper can usually reach more than 97% and the reverse extraction rate can reach more than 98% through the extraction of 3 to 5 stages. Through electrolytic recovery, the obtained metal copper can meet the requirements of the national standard GB/T467-1997 "cathode Copper" No. 1 standard. In this process, pretreatment of materials, preparation of extractant, comparison control and post-treatment are very important to the extraction rate and purity of copper. The extraction process of alkaline etching liquid almost does not extract ammonia, and after pH adjustment, it can be returned to the etching operation to achieve recycling and achieve zero external pollution.

Hot spot

Welcome to contact you by phone

Working hours(8:30-20:30)Enquiry hotline

+86 13255260239

Pay attention to customer service wechat

Working hours(8:30-20:30)