News Center

social responsibility

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

![]() Release date:2024.09.13

Release date:2024.09.13

![]() Page view:76

Page view:76

With the growing demand for structural and functional materials in emerging industries, rare metals, dispersed metals and rare earth metals (the "three rare" resources) have become the main sources. Among the many rare metal elements, rubidium (Rb) and cesium (Cs), two rare and precious metals and their compounds, are widely used in the fields of electronics, glass, chemical industry, energy and medicine because of their enhanced chemical activity and superior photoelectric properties. With the rapid development of high-tech industry at home and abroad, the demand for rubidium, cesium and their compounds has become more and more urgent.

Rubidium and cesium are known as "metals with long eyes", they have good ductility, excellent electrical and thermal conductivity, and excellent photoelectric effect characteristics. Therefore, they are widely used in communication, military, aerospace, energy conversion, electronic devices, biology, medicine and chemical and chemical industries. Rubidium and cesium can be used as important additive materials for infrared radiation sources, atomic clocks, magnetic fluid generators, thermionic power generation, ion engines, hollow cathode lamps, multiplier tubes, vidicon tubes, micro batteries, scintillation counters, lasers, special glasses, DNA separation, sedatives and catalysts. In recent years, the growing demand for rubidium and cesium has driven the development of the rubidium cesium industry.

Rubidium and cesium are widely found in lepidolite, salt lake brine and high salt waste. The separation methods of rubidium cesium mainly include precipitation, ion exchange and solvent extraction. Among them, the centrifugal solvent extraction method has the advantages of rapid reaction, large processing capacity, simple operation and easy realization of continuity. In recent years, this method has been extensively studied, and has achieved the fastest technical progress and the greatest application potential.

Solvent extraction method realizes the separation of different ions by selective extractant. Among them, 4-tert-but-2 - (α-benzyl) phenol (t-BAMBP), as a special extractant, has the advantages of low water solubility, good stability, non-toxic, strong selectivity, rapid reaction, high extraction efficiency, easy extraction and recycling, and has been widely used in the separation of rubidium and cesium. Under alkaline conditions, t-BAMBP has a different extraction sequence for rubidium and cesium, so the separation of cesium rubidium can be achieved. In engineering applications, the feed liquid is first pretreated to reduce the potassium content. After multi-stage centrifugal extraction, washing and stripping, the extraction rates of rubidium and cesium can generally reach more than 95% under reasonable extraction agent allocation and comparison.

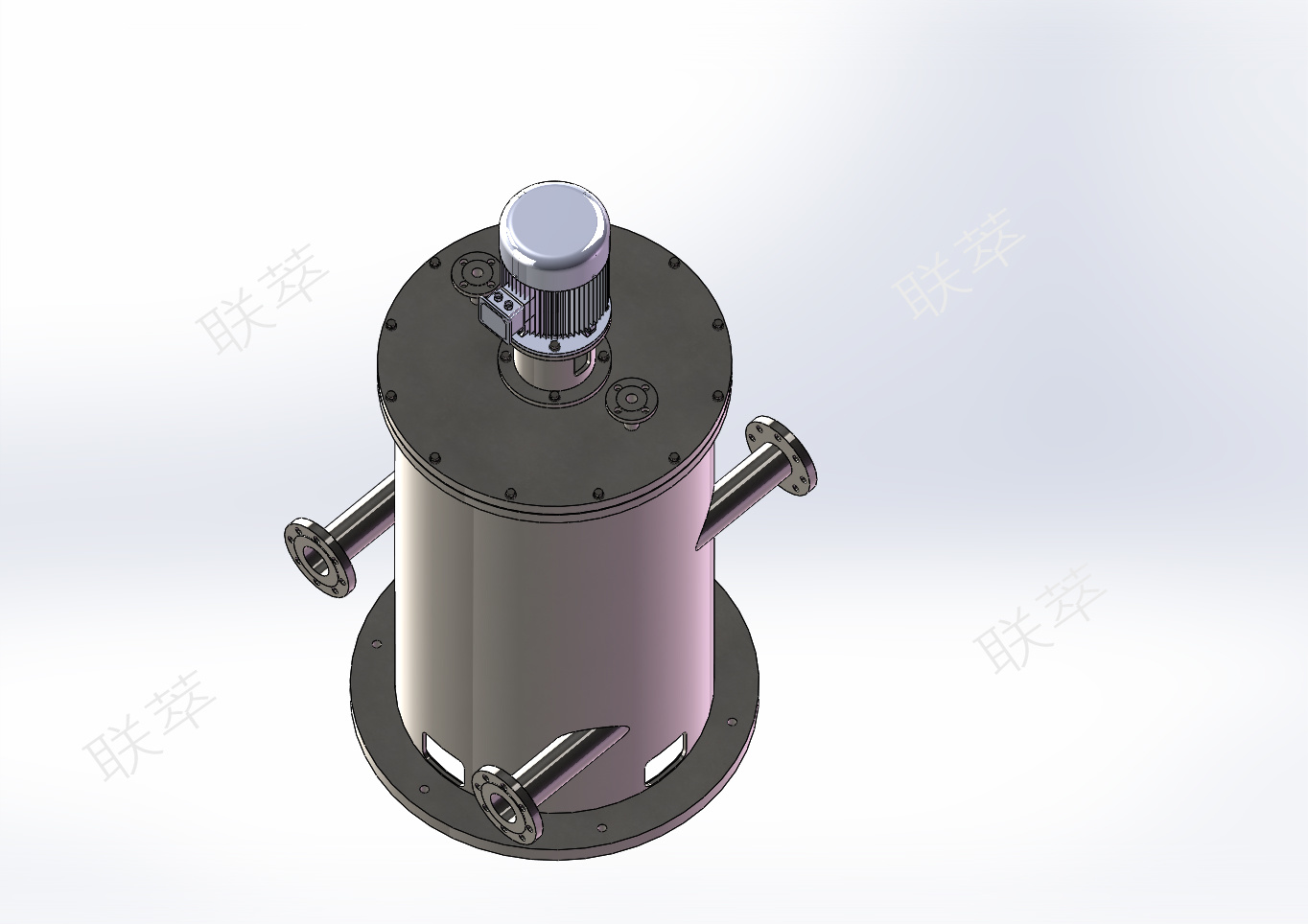

At present, organic reagents with good rubidium cesium ion extraction performance include phenolic alcohol reagents, crown ether, dipicrylamine and its derivatives and nitro compounds. However, ether extractants such as crown ether and cup aryl crown ether are not suitable for industrial applications due to the difficulty of extraction. Dipicrylamine and its derivatives and nitro compounds are rarely reported because of their own difficulties. In addition to extractors, as the core equipment of centrifugal solvent extraction, Shandong Lian-extract centrifugal extractor has technical advantages such as high technical parameters, large aspect ratio, and low shear of overhanging type, which is the necessary guarantee for achieving high extraction rate of rubidium cesium separation.

Hot spot

Welcome to contact you by phone

Working hours(8:30-20:30)Enquiry hotline

+86 13255260239

Pay attention to customer service wechat

Working hours(8:30-20:30)