News Center

social responsibility

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

![]() Release date:2024.11.05

Release date:2024.11.05

![]() Page view:63

Page view:63

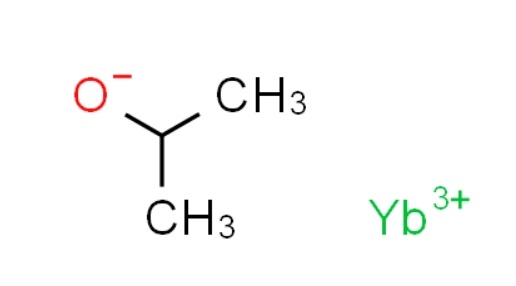

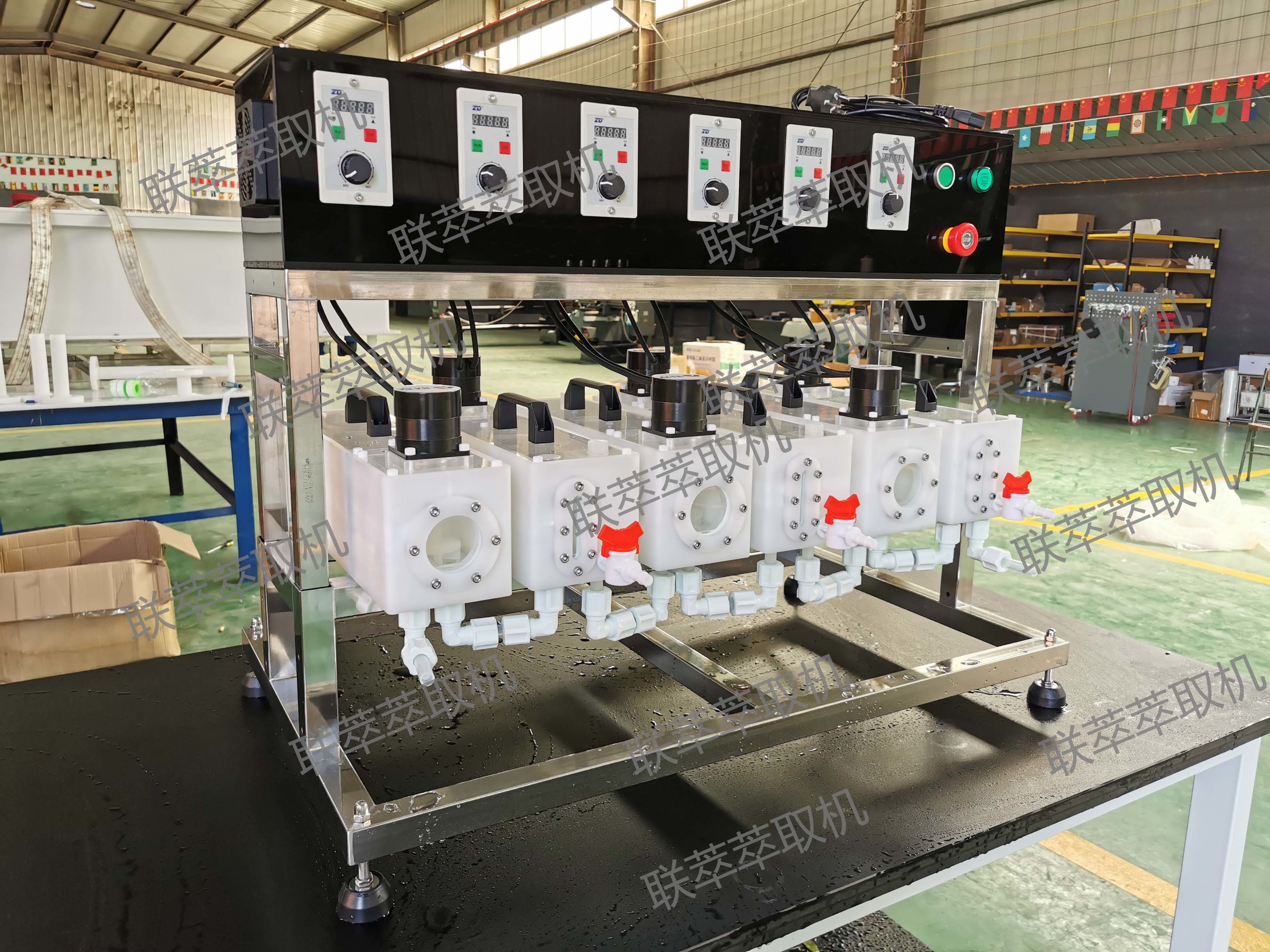

In view of its wide application as an important organic solvent in chemical and pharmaceutical fields and its potential environmental risks, the use of centrifugal extraction technology as an efficient liquid-liquid separation means is particularly important. By strengthening the centrifugal force, the centrifugal extractor realizes the rapid and effective separation of fluids with different densities, which is especially suitable for the separation and recovery of isopropyl ether and isopropyl alcohol.

The professional procedure is summarized as follows:

Pretreatment stage: The first step is to pretreat the organic wastewater containing isopropyl ether and isopropyl alcohol in order to remove solid impurities and suspended particles in the wastewater and ensure the fluency and efficiency of the subsequent extraction operation. This pretreatment step is essential to ensure the long-term stable operation of the extraction system.

Extraction agent selection: Ethylene glycol is selected as the extraction agent, because of its excellent selectivity and chemical stability, can effectively improve the separation efficiency between isopropyl ether and isopropyl alcohol. Ethylene glycol was chosen to simplify the separation process by increasing the relative volatility between components and breaking the potential azeotropic state.

Mixing and mass transfer: the pre-treated wastewater and ethylene glycol extractant are simultaneously introduced into the annular gap mixing zone formed between the drum and the shell of the centrifugal extractor in a predetermined proportion. The rotating drum drives the turbine disc and impeller to promote the rapid mixing and dispersion of the two-phase fluid, ensuring an efficient mass transfer process and laying the foundation for subsequent separation.

Centrifugal separation: Under the guidance of the vortex disk, the mixed liquid enters the inside of the drum. Under the action of centrifugal force, the dense heavy phase (rich in isopropyl ether and extractant) gradually gets close to the drum wall during the upward migration process, while the light phase (mainly containing isopropyl alcohol and water) with less density gathers towards the center of the drum. This process achieves effective separation of the two phases.

Collection and recovery: After centrifugal separation, the clarified two-phase liquid enters the collection chamber through the respective weir plates and is exported by the lead pipe to the external system to complete the final separation process. The separated isopropyl ether and isopropyl alcohol can be recovered and reused respectively, which realizes the effective recycling of resources.

The separation and recovery of organic wastewater containing isopropyl ether and isopropyl alcohol by centrifugal extractor is not only technically feasible, but also has the advantages of high efficiency and economy. By carefully selecting extractants, optimizing operating conditions and strengthening equipment maintenance, the separation efficiency can be further improved, and the double improvement of environmental and economic benefits can be achieved.

Hot spot

Welcome to contact you by phone

Working hours(8:30-20:30)Enquiry hotline

+86 13255260239

Pay attention to customer service wechat

Working hours(8:30-20:30)