News Center

social responsibility

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

![]() Release date:2024.10.31

Release date:2024.10.31

![]() Page view:65

Page view:65

Resorcinol, chemical name 1, 3-resorcinol, exists in nature in its white needle-like crystal or powder form, has unique solubility characteristics, especially soluble in a variety of organic solvents. In chemical production and laboratory analysis, the extraction of resorcinol is a crucial step, which depends on the difference of solubility between solvents, and the separation of target substances by solvent extraction or liquid-liquid extraction technology.

Raw material preparation:

First, 6000g of saline solution containing 6.5% resorcinol was prepared as extraction raw material.

Extractant selection:

According to the dissolution characteristics of resorcinol, high efficiency extractants such as methyl isobutyl ketone, cyclohexanol or cyclohexanone were selected and 3000g was prepared for use.

Extraction operation:

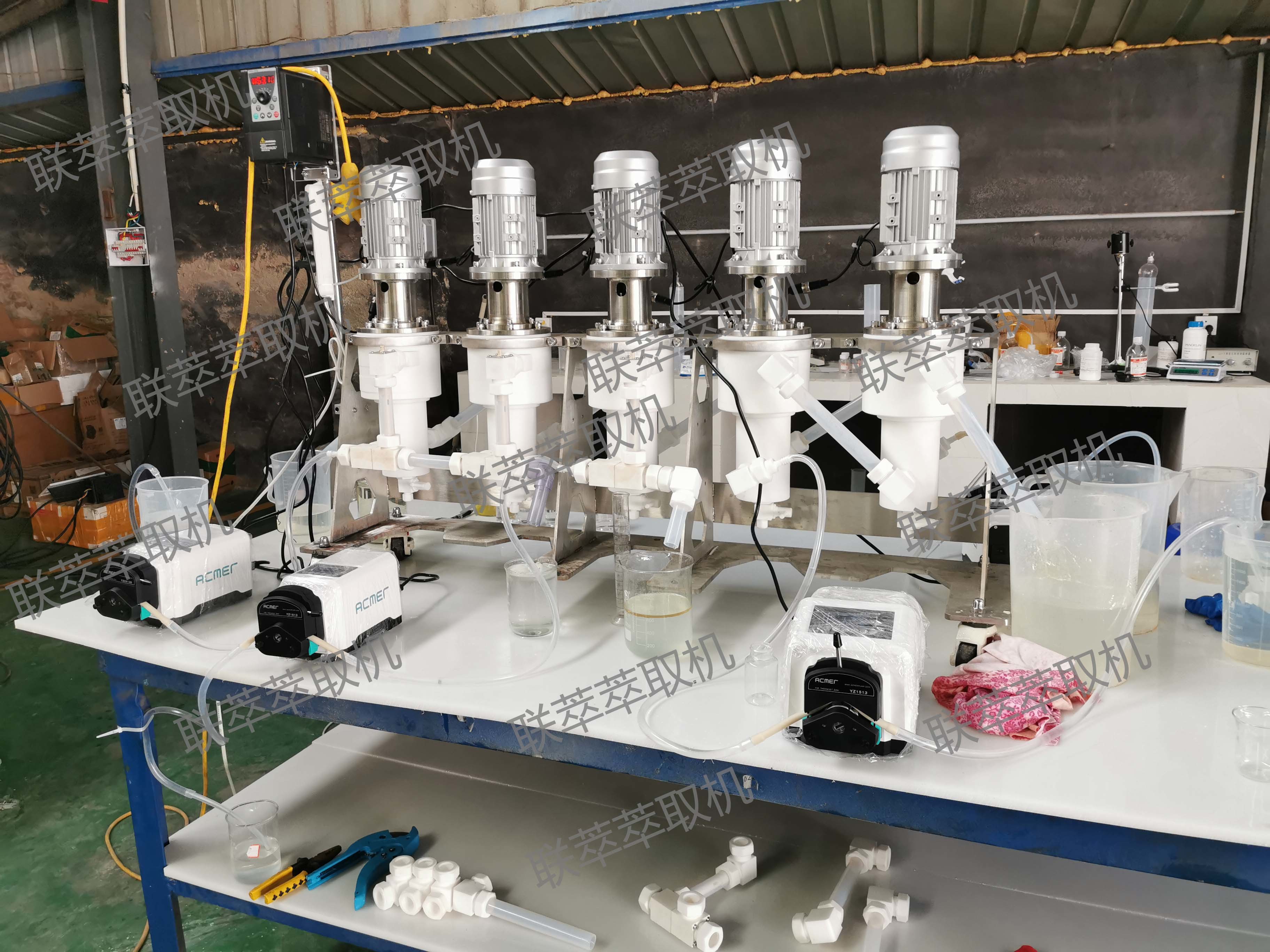

Equipment start: start the combined extraction centrifugal extractor, adjust it to the best working state, ensure that the speed is stable at 3000rpm, to provide strong centrifugal force support.

Feed control: the raw material solution is uniformly added from the feed port of the first stage combined extraction centrifugal extractor, and the feed speed is set at 200g/min; At the same time, the extractant is reversely added from the feed port of the third stage centrifugal extractor, and the feed speed is set to 100g/min to form a countercurrent extraction system.

Countercurrent extraction: Under the powerful centrifugal force of the combined extraction centrifugal extractor, the solute (isophenol) and the solvent (extractant) are fully contacted and efficiently separated in the extractor at all levels to achieve the three-stage countercurrent extraction process.

Separation and collection:

Extraction liquid collection: After extraction was completed, the extraction liquid rich in resorcinol was collected from the discharge port of the first stage combined extraction centrifugal extractor. The oil layer weight was about 3392.5g, and the content of resorcinol was increased to 11.4% after detection.

Wastewater treatment: The wastewater is discharged from the discharge port of the third-stage centrifugal extractor, and the analysis and verification show that the content of phlorcinol is very low, only 0.056%, which meets the environmental protection discharge standard.

Extraction efficiency:

The three-stage countercurrent extraction process carried out by the combined extraction centrifugal extractor not only significantly improves the extraction efficiency of lorcinol to 99.2%, but also shows its comprehensive advantages in treatment efficiency, resource utilization and environmental protection, reflecting the characteristics of efficient and economical production.

The combined extraction centrifugal extractor plays a key role in the extraction process of resorcinol. Through its unique centrifugal extraction technology and counter-current operation mode, it realizes the efficient and pure extraction of resorcinol, providing strong technical support and guarantee for related industries.

Hot spot

Welcome to contact you by phone

Working hours(8:30-20:30)Enquiry hotline

+86 13255260239

Pay attention to customer service wechat

Working hours(8:30-20:30)