News Center

social responsibility

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

![]() Release date:2024.10.21

Release date:2024.10.21

![]() Page view:80

Page view:80

In the recovery process of rhenium elements, leaching method, as a key step in the early treatment, is very important for the enrichment and initial separation of rhenium. For different resource sources, such as primary resources and secondary resources, a variety of leaching methods were used, such as roasting leaching, alkali roasting leaching, oxidation leaching, electrooxidation leaching, pressure leaching, displacement leaching, etc., to effectively extract and enrich rhenium elements. These processes make rhenium finally stable in the solution in the form of ReO4-, laying the foundation for the subsequent purification and recovery stage.

In the purification and recovery stage, solvent extraction and ion exchange have become the mainstream technologies because of their high efficiency and practicability. Although precipitation has a certain application in industrial recycling, emerging technologies such as activated carbon adsorption and raffinate resin are still limited by technical maturity and cost considerations, and are still in the laboratory research stage. Solvent extraction method is widely used in rhenium recovery process because it realizes high efficiency extraction and separation of rhenium based on the principle of solubility or partition coefficient difference between solutes.

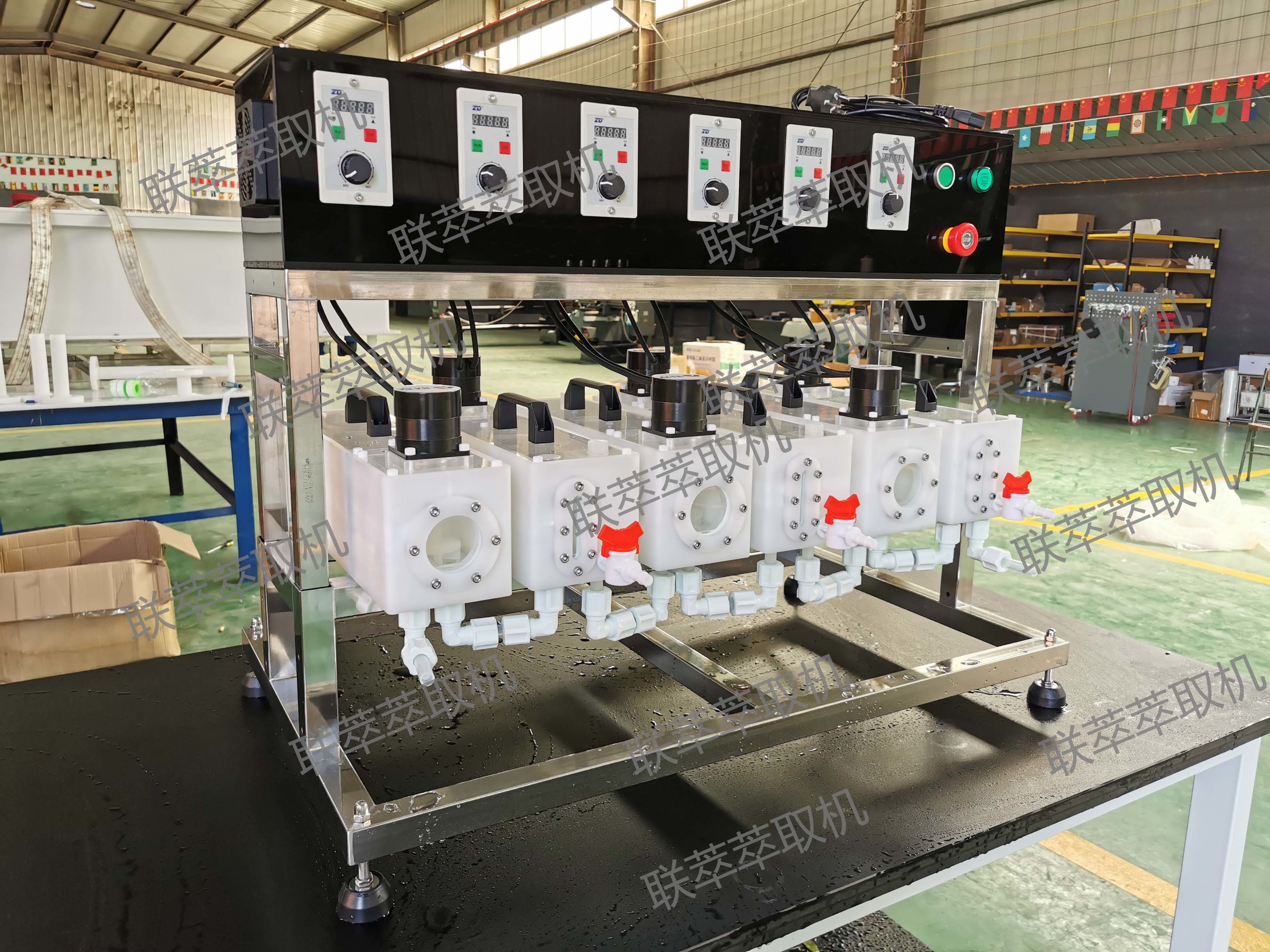

In particular, the rhenium sulfide is converted to volatile Re2O7 by roasting minerals and then dissolved in solvents, using advanced centrifugal extraction systems, such as Shandong Liucent centrifugal extraction machine, with its high separation factor, corrosion resistance and strong mass transfer capacity, to achieve efficient enrichment and recovery of rhenium. This process not only increases the rhenium recovery rate to more than 95%, but also ensures the high purity of the product, meeting the strict requirements of high-end applications.

With the vigorous development of science and technology, aerospace and other fields, the demand for rhenium as a strategic metal element will continue to grow, is expected to 2030, China's demand for rhenium or will achieve two to three times the growth. Therefore, the clean, efficient enrichment and recycling of rhenium resources has become an important issue to be solved urgently, which has far-reaching strategic significance for promoting the sustainable use of resources and the long-term development of the country.

Centrifugal solvent extraction technology shows great application potential because of its high extraction efficiency, recyclable extractant and small stage retention. In the future, with the continuous progress of technology and the continuous optimization of costs, the technology is expected to play a more active role in the field of rhenium element recovery, and contribute to the dual goals of maximizing the utilization of rhenium resources and environmental protection.

Hot spot

Welcome to contact you by phone

Working hours(8:30-20:30)Enquiry hotline

+86 13255260239

Pay attention to customer service wechat

Working hours(8:30-20:30)