News Center

social responsibility

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

![]() Release date:2024.10.18

Release date:2024.10.18

![]() Page view:69

Page view:69

Rhenium (Re), as a rare metal with high temperature resistance, high thermal conductivity, high hardness and excellent creep resistance, its strategic position in petrochemical, electronics, aerospace, nuclear energy, medical and environmental protection and other fields irreplaceable, especially in the aviation engine manufacturing of the key role, making it an important strategic resource of the country. Due to its extremely low abundance in the Earth's crust (about 0.63×10^-9), efficient recovery and utilization of rhenium resources is particularly important.

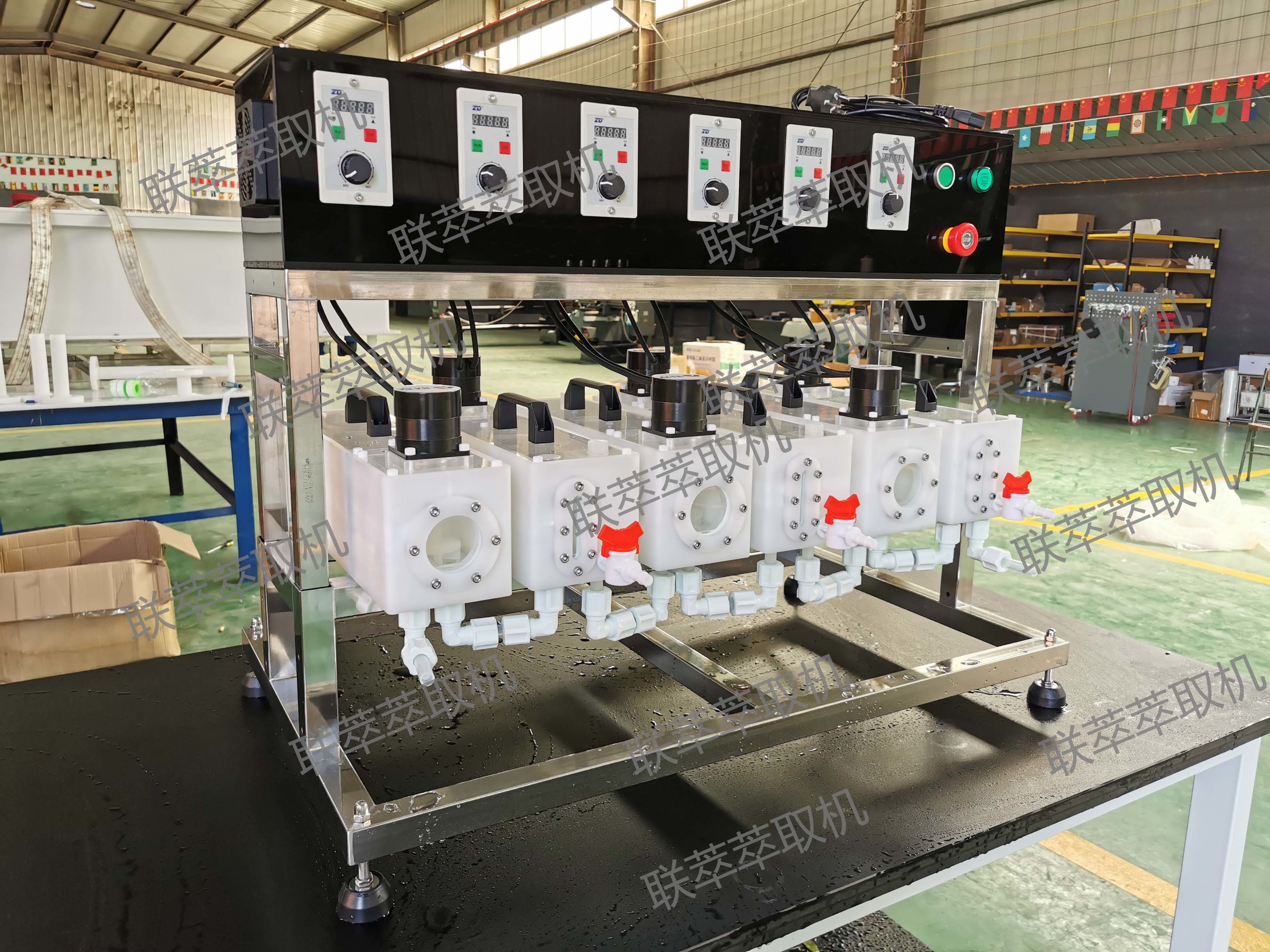

In the process of copper smelting, rhenium is mainly volatilized in the form of Re2O7 and concentrated in dirty acid, which makes it possible to recover rhenium. Therefore, a set of rhenium extraction system based on solvent extraction technology was developed. The system integrated key unit operations such as feed-liquid pretreatment, extraction agent precise formulation, CTX multistage centrifugal extraction - washing - stripping, evaporation concentration, freezing crystallization and centrifugal filtration, and formed a set of efficient and stable rhenium extraction equipment. The device can flexibly respond to fluctuations in rhenium concentration in the raw material, ensuring that the final product - ammonium rhenate (NH4ReO4) purity of more than 99%, and excellent crystal form, to meet the needs of high-end applications.

In particular, the combined extraction multistage centrifugal extractor plays a central role in the system. Through the design of multistage countercurrent extraction, the extraction efficiency and selectivity are effectively improved, the solvent consumption is reduced, and the efficient enrichment and separation of rhenium is ensured. At the same time, the application of centrifugal extractor also simplifies the operation process, improves the degree of automation and stability of the system, and provides solid technical support for large-scale industrial extraction of rhenium.

In view of the homogeneous existence of rhenium in molybdenum ore, copper ore and other sulfide deposits, and the relatively high content of rhenium in these ores, the centrifugal extraction system is also suitable for molybdenum ore rhenium extraction process. By optimizing roasting, leaching, extraction, back extraction, ion exchange and subsequent treatment steps, rhenium elements can be effectively extracted and recovered from copper concentrate and molybdenum concentrate, which further expands the source channel of rhenium resources.

The multi-stage system of centrifugal extractor has shown remarkable technical advantages and economic value in the efficient extraction of rhenium. In the future, with the continuous progress of technology and the in-depth expansion of applications, the system is expected to achieve efficient recovery and utilization of rhenium resources in more fields, and contribute to the national strategic resource security and sustainable development.

Hot spot

Welcome to contact you by phone

Working hours(8:30-20:30)Enquiry hotline

+86 13255260239

Pay attention to customer service wechat

Working hours(8:30-20:30)