News Center

social responsibility

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

![]() Release date:2024.10.15

Release date:2024.10.15

![]() Page view:88

Page view:88

In the pharmaceutical industry, vitamin E as a key nutritional health products and pharmaceutical ingredients, its quality and purity are directly related to the market competitiveness of products and consumer health. With the continuous growth of natural vitamin E market demand, and the wide application of synthetic vitamin E in the global market, how to efficiently and stably extract and purify these high-boiling, heat-sensitive fat-soluble ingredients has become the focus of the industry.

Traditional distillation is often faced with the challenges of variability and high energy consumption when dealing with heat sensitive substances such as vitamin E. Molecular distillation technology with its unique advantages, such as low operating temperature, high separation degree, no impurity introduction and continuous production characteristics, become the ideal choice to improve the quality and yield of vitamin E. On this basis, the introduction of the combined extraction centrifugal extractor has brought a developmental change to this purification process.

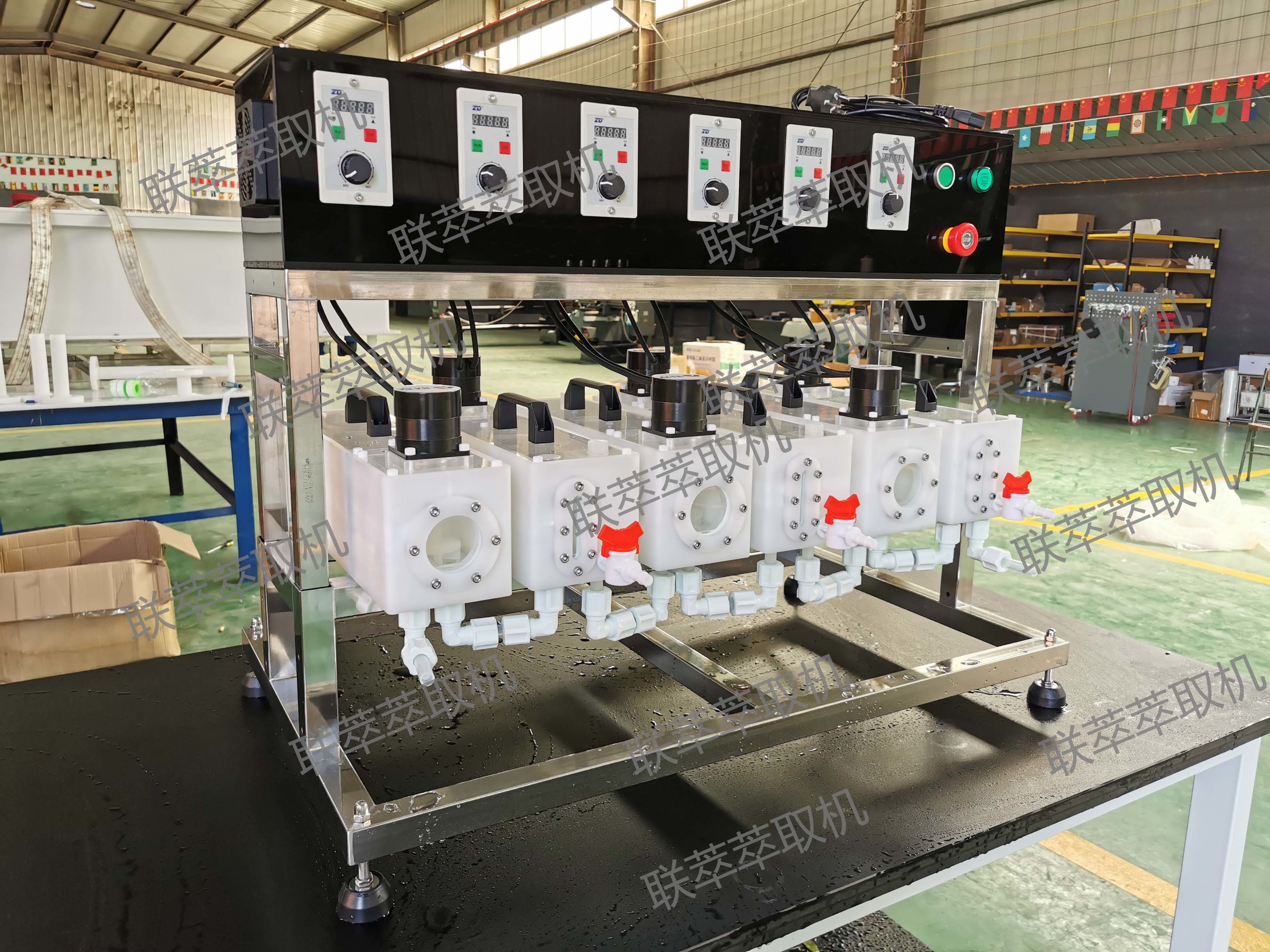

With its efficient extraction and separation capabilities, the combined extraction centrifugal extractor can accurately extract vitamin E from complex animal and plant tissues under mild conditions, effectively avoiding the high temperature damage and energy waste of traditional methods. At the same time, its unique rotor design and the effect of centrifugal force field promote the full contact and rapid phase separation between the material and the extractant, and improve the extraction efficiency and purity.

In the purification process of vitamin E, the combined extraction centrifugal extractor can be seamlessly connected with molecular distillation technology to form a complete purification solution. First, the raw material is efficiently pretreated by a combined extraction centrifugal extractor to remove most impurities and provide a high-quality feed for subsequent molecular distillation. Subsequently, molecular distillation technology was used to further purify vitamin E to achieve the goal of high purity and high yield.

In addition, the combined extraction centrifugal extracter has shown broad application prospects in the production of other high-value ingredients such as squalene, long-chain aliphatic anols, and patchouli essential oil. These components also have the characteristics of high thermal sensitivity and difficult separation, and the combination of combined extraction centrifugal extractor and molecular distillation technology provides efficient and reliable technical support for their purification and preparation.

The combined extraction centrifugal extracter plays an important role in the purification of vitamin E and other high-value ingredients in the pharmaceutical industry, which not only improves product quality and output, but also promotes the technological progress and green development of the entire industry.

Hot spot

Welcome to contact you by phone

Working hours(8:30-20:30)Enquiry hotline

+86 13255260239

Pay attention to customer service wechat

Working hours(8:30-20:30)