News Center

social responsibility

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

![]() Release date:2024.10.11

Release date:2024.10.11

![]() Page view:72

Page view:72

Beryllium, as a key strategic material, plays an irreplaceable role in many high-tech fields such as atomic energy, aerospace, metallurgy and so on. Given its importance and scarcity, efficient extraction of beryllium from beryllium-containing stock solutions is a critical technical challenge. Under this background, the centrifugal solvent extraction method combined with the application of combined extraction centrifugal extractor provides an efficient and stable way for the extraction of beryllium.

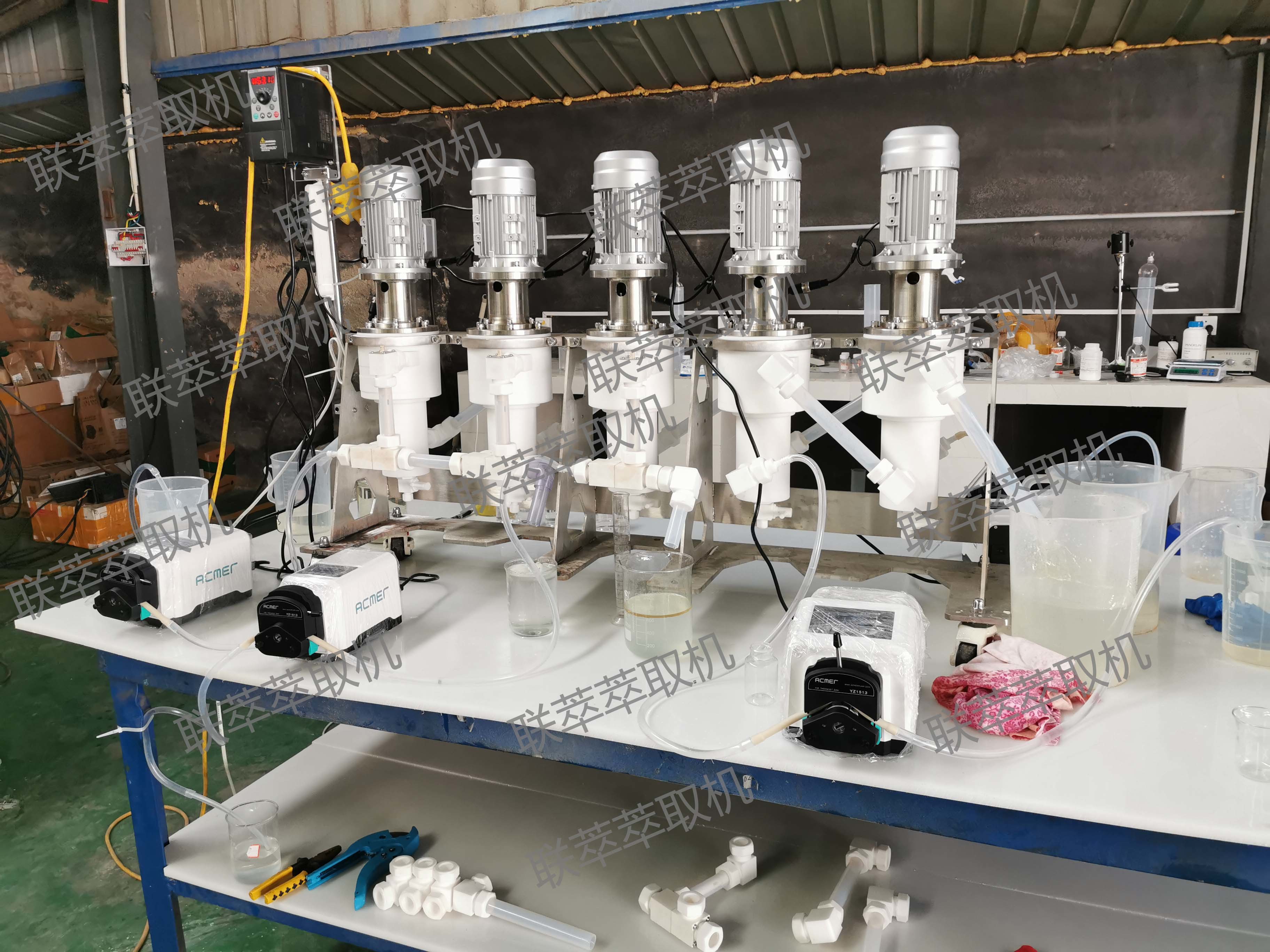

With P204, sulfonated kerosene and isoamyl alcohol as the complex extractants, the highly efficient and selective extraction of beryllium in beryllium-containing stock solution was realized through the carefully designed ratio. In the extraction process, the combined extraction centrifugal extractor, with its excellent centrifugal separation capacity and efficient mass transfer performance, ensures full contact and rapid phase separation between the extractant and the beryllium-containing stock solution, thus greatly improving the extraction efficiency and purity.

Then, the loaded organic phase containing beryllium enters the washing process through the series countercurrent operation of the multistage combined extraction centrifugal extracter. At this stage, oxalic acid and sodium sulfite are used as detergent, and the impurity ions in the loaded organic phase are effectively removed by the fine washing of the combined extraction centrifugal extractor, which lays a good foundation for the subsequent stripping process.

In the back extraction process, the dilute lye is introduced into the system as the back extraction agent, and the efficient transfer of beryllium from organic phase to aqueous phase is realized through the multi-stage back extraction stage of the combined extraction centrifugal extractor. In this process, the precise control and efficient phase separation capabilities of the combined extraction centrifugal extractor were once again verified, ensuring high recovery of beryllium elements.

After the separation of oil and water, the concentration of beryllium in the water phase containing beryllium is high and the impurity is less, which provides high quality raw materials for the preparation of beryllium products. In the whole process of extracting beryllium, the application of combined extraction centrifugal extractor not only improves extraction efficiency and product quality, but also reduces energy consumption and production cost, showing its strong strength and wide application in the field of complex metal element extraction

Hot spot

Welcome to contact you by phone

Working hours(8:30-20:30)Enquiry hotline

+86 13255260239

Pay attention to customer service wechat

Working hours(8:30-20:30)