News Center

social responsibility

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

![]() Release date:2024.10.10

Release date:2024.10.10

![]() Page view:72

Page view:72

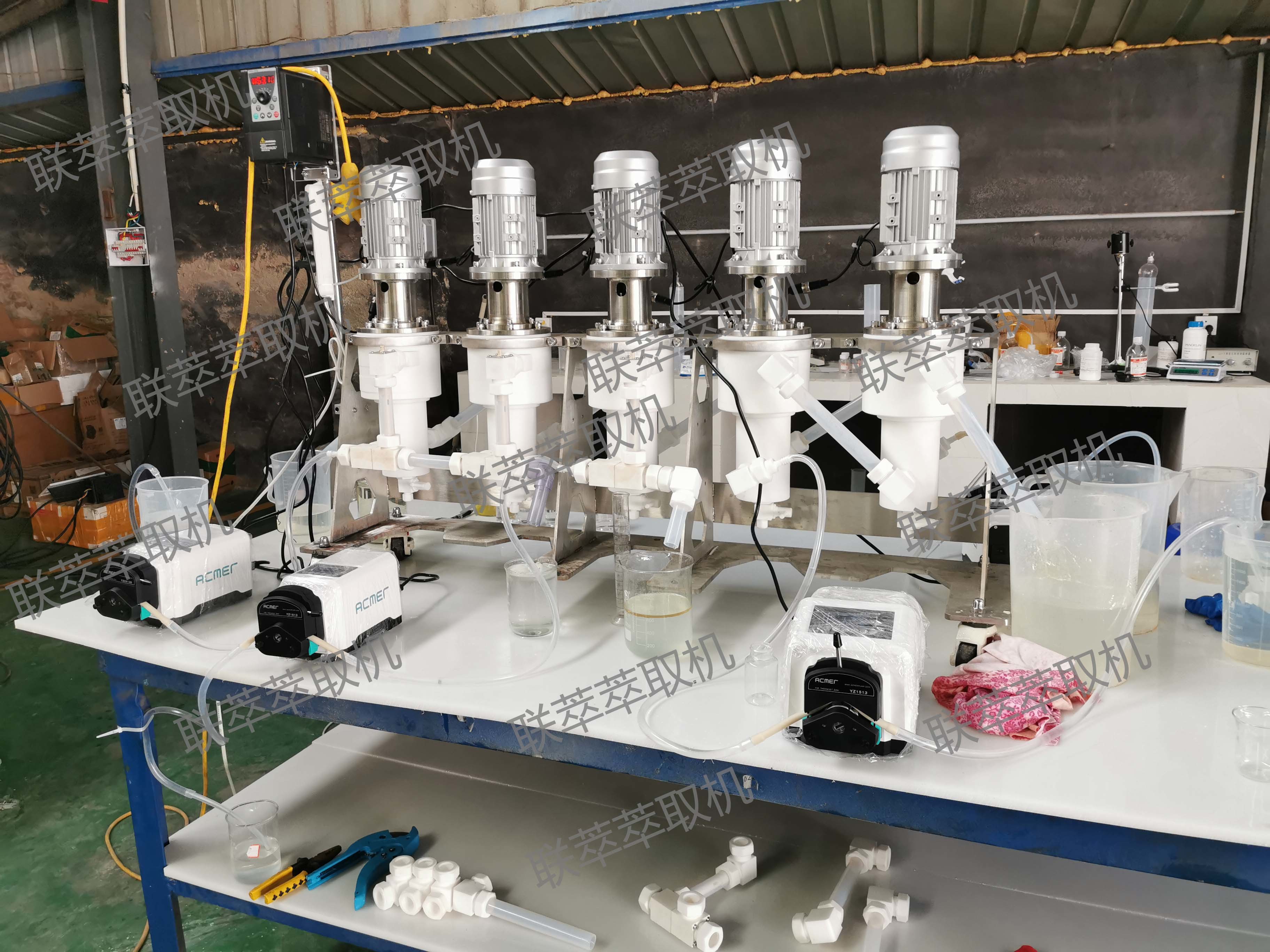

In the field of hydrometallurgy, solvent extraction technology as an important means to extract and separate metal elements, its equipment types are diverse, among which the combined extraction centrifugal extraction machine with its special centrifugal field phase separation technology, showing excellent separation performance and technological advantages. This technology not only improves the extraction efficiency, reduces the level retention, but also optimizes the mass transfer effect, shortens the material residence time, effectively saves the floor area, and is easy to realize fully automated process control, so it has been widely used in the extraction and separation of rare and precious metals such as nickel, cobalt, copper, gold, silver, scandium, francium, uranium, thorium, rhenium, zinc.

In view of the rhenium recovery problem in the flue gas washing liquid of a copper smelter, the solution contains sulfuric acid medium (H2SO4 concentration 10% ~ 20%), and contains a small amount of fluoride ions and chloride ions, the rhenium content range is 5 ~ 40 mg/L, and the temperature is maintained at 40 ~ 50 ℃. In order to extract rhenium in this solution efficiently, the process first uses vacuum filtration to remove insoluble impurities, and then uses a combined extraction centrifugal extractor to carry out three-stage centrifugal extraction. This link gives full play to the characteristics of the high separation factor of the combined extraction centrifugal extractor, ensuring the high efficiency and accuracy of the extraction process.

After extraction is complete, the raffinate goes directly into the subsequent wastewater treatment process, while the loaded organic phase is further purified by two-stage centrifugal washing. Subsequently, the no-load organic phase obtained by the three-stage centrifugal stripping operation can be recycled, which not only saves resources but also reduces costs. The rhenium-rich liquid enters the evaporation and concentration stage, and after freezing crystallization and centrifugal filtration, the crude ammonium rhenate crystal is obtained. In this process, the application of the combined extraction centrifugal extractor in several key steps ensures the high efficiency and stability of the entire extraction process.

Hot spot

Welcome to contact you by phone

Working hours(8:30-20:30)Enquiry hotline

+86 13255260239

Pay attention to customer service wechat

Working hours(8:30-20:30)