News Center

social responsibility

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

![]() Release date:2024.10.09

Release date:2024.10.09

![]() Page view:76

Page view:76

DMF (N, N-dimethylformamide) is known as "universal solvent" because of its powerful dissolution ability. In addition, DMF is also used as an organic synthesis raw material, widely used in polyurethane synthetic leather, pesticide and pharmaceutical intermediates, food, electronics, dyes, fibers, petrochemical and metallurgical industries. However, the amount of DMF wastewater produced in China every year is large, and the annual discharge of DMF wastewater in the synthetic leather industry alone is as high as 100 million tons. Therefore, the treatment of DMF wastewater is not only environmental protection needs, but also has significant economic benefits.

The traditional DMF wastewater treatment method mainly uses rectification method, but this method has low recovery rate, high energy consumption, and will produce toxic and harmful dimethylamine gas, which will bring harm to the environment and operators. In order to overcome these technical defects, the industry has innovated a new process technology of "extraction-rectification-adsorption-thermal analysis" to carry out comprehensive treatment of DMF wastewater. The technology has shown remarkable energy-saving effect in practical application, energy consumption can be reduced by more than 50%, DMF recovery rate is high, the DMF content in the extracted wastewater is < 1%, and the obtained DMF purity is high, no toxic and harmful gases are produced, and the secondary pollution of the environment is avoided.

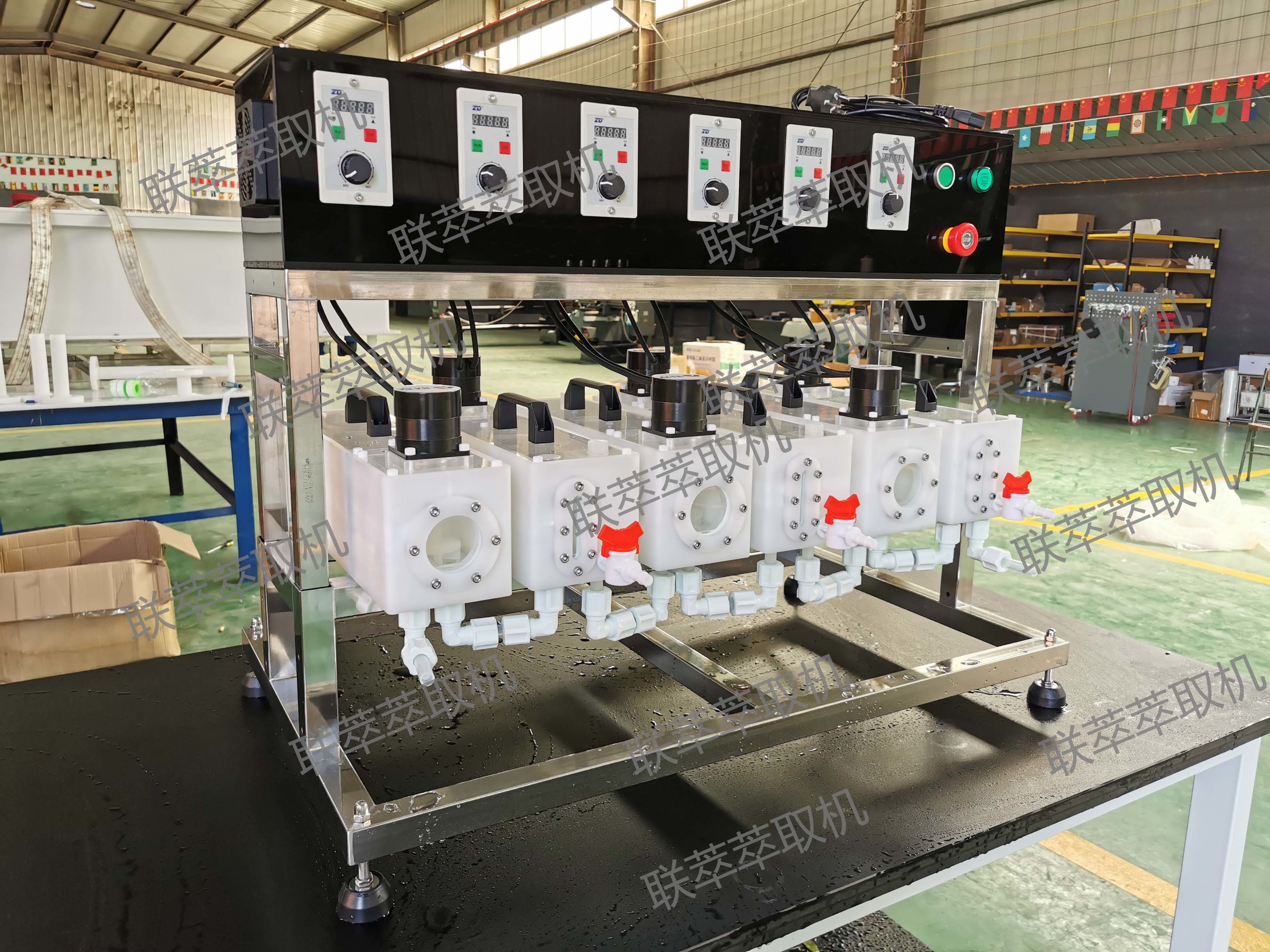

The combined extraction centrifugal extractor uses corrosion-resistant spray fluorine material and polymer perfluorinated material rotor to ensure the durability and reliability of the equipment in the treatment of DMF wastewater.

The equipment is equipped with an efficient stirring mass transfer device, which greatly improves the extraction efficiency and enables DMF to be efficiently recovered.

These designs not only improve the stability and operating efficiency of the equipment, but also reduce energy consumption and further reduce operating costs.

Through its high-speed rotation and powerful centrifugal force, the combined extraction centrifugal extractor achieves efficient substance separation, significantly improves the recovery rate of DMF, and ensures that the DMF content in the extracted wastewater is less than 1%.

The design of the equipment fully considers the factors of energy conservation and environmental protection, the energy consumption is greatly reduced, no toxic and harmful gas emissions, and the secondary pollution of the environment is avoided.

The efficient operation and low maintenance cost of the equipment significantly improve the economic benefits of the enterprise. In addition, the footprint is small, the operation and maintenance is convenient, which greatly reduces the operation and maintenance costs of enterprises.

The combined extraction centrifugal extractor can establish the phase balance in a short time, ensure the efficient and stable operation of the entire extraction process, and further improve the processing capacity.

Hot spot

Welcome to contact you by phone

Working hours(8:30-20:30)Enquiry hotline

+86 13255260239

Pay attention to customer service wechat

Working hours(8:30-20:30)