News Center

social responsibility

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

![]() Release date:2024.09.10

Release date:2024.09.10

![]() Page view:93

Page view:93

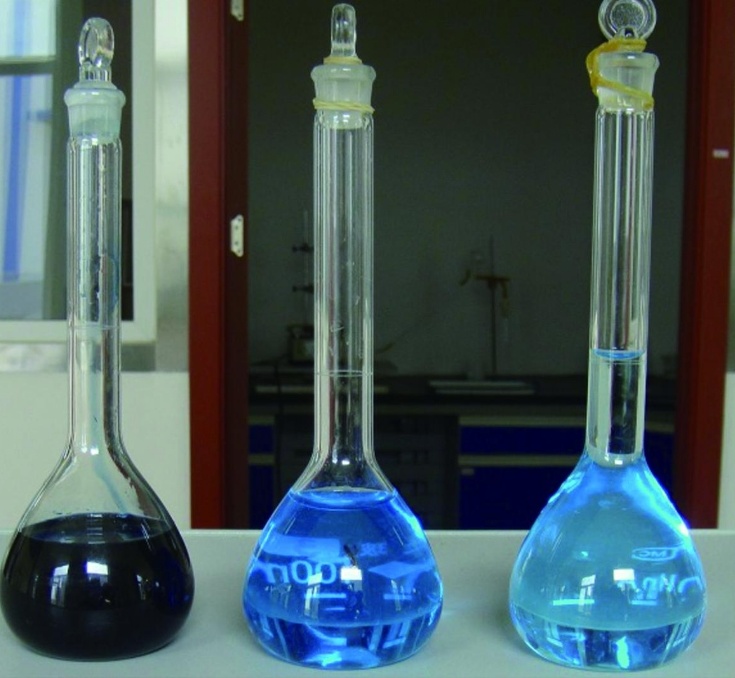

Electrolyte is an important part of lithium battery, and its quality and purity have a key impact on battery performance. This paper will introduce the method of calculating the cost per ton of electrolyte and its production process.

The cost of electrolyte is mainly composed of raw material cost, labor cost and energy consumption cost. The cost of raw materials is the main component of the cost of electrolyte, of which the cost of solvent accounts for the highest proportion, reaching more than 80%, and the cost of electrolyte lithium salt and additives is relatively low. Labor costs include operating workers' wages and training costs. Energy consumption costs include the cost of energy consumption such as electricity, water and gas. By calculating the purchase price and amount of raw materials, labor cost and energy consumption cost, the cost of a ton of electrolyte can be obtained.

The production process of electrolyte mainly includes raw material procurement, purification and proportioning, mixing, filtration and filling steps. First, the purity and quality of the electrolyte are ensured by selecting raw materials such as high purity organic solvents, electrolyte lithium salts and necessary additives. Then, the raw material is purified, including distillation and filtration of solvent, crystallization and drying of electrolyte lithium salt and other steps. Next, the raw materials are added to the mixing equipment in accordance with a certain proportion for full mixing. During the mixing process, attention should be paid to controlling the temperature and time to ensure the uniform mixing of raw materials. After mixing, the electrolyte is filtered to remove suspended solids and impurities. Finally, the filtered electrolyte is filled for subsequent use or sale.

The cost per ton of the electrolyte can be obtained by calculating factors such as raw material cost, labor cost and energy cost. The production process of electrolyte includes the steps of raw material procurement, purification and matching, mixing, filtration and filling. By controlling the purity of the raw material, the purification process and environmental conditions, the quality and performance of the electrolyte can be ensured.

Hot spot

Welcome to contact you by phone

Working hours(8:30-20:30)Enquiry hotline

+86 13255260239

Pay attention to customer service wechat

Working hours(8:30-20:30)