News Center

social responsibility

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

![]() Release date:2024.09.09

Release date:2024.09.09

![]() Page view:93

Page view:93

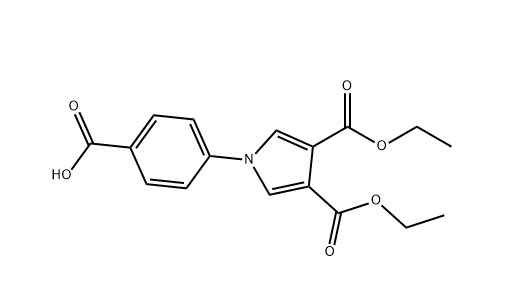

The preparation of high pressure lithium iron phosphate by ferrous oxalate method is a common preparation method, which has the characteristics of simple and good controllability. With the increasing application of lithium iron phosphate in the field of energy storage, combined extraction centrifuge, as an efficient separation equipment, has an important application in this process.

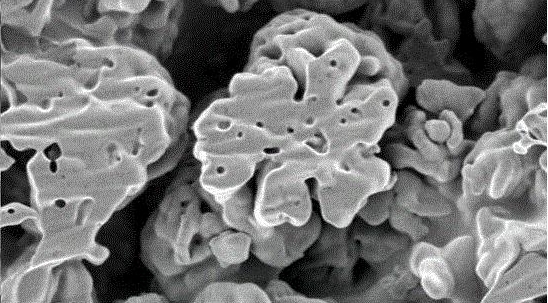

The process of preparing high pressure lithium iron phosphate by ferrous oxalate method mainly includes the following steps: raw material batching, drying, sintering, grinding and mixing. In the dosing stage, the proportion and quality of raw materials need to be accurately controlled to ensure the stability and performance of the final product. Next, the drying process removes water from the raw material and improves the sintering effect. Then, the sintering process is carried out, and the raw material is burned into lithium iron phosphate particles at high temperatures. The sintered particles need to be crushed and mixed to obtain uniform particles and chemical composition.

The combined extraction centrifuge has an important application in the process of preparing high pressure lithium iron phosphate by ferrous oxalate method. First of all, the combined centrifuge can be used for grinding and mixing processing to achieve the uniformity of particles and the uniformity of chemical composition. By adjusting parameters such as centrifugal force and temperature, efficient separation and purification of target components can be achieved.

Centrifuges can also be used for product purification and separation. In the preparation process of lithium iron phosphate, there may be impurities, which can be removed by the application of centrifuge to improve the purity and activity of the product.

The in situ monitoring function of the centrifuge can monitor the material behavior in the preparation process in real time and provide important data support. Through on-line study of the process and influencing factors in the preparation process, the process conditions can be optimized and the performance and quality of the product can be improved.

The preparation of high pressure lithium iron phosphate by ferrous oxalate method is a common preparation method, which is of great significance in the application of centrifuge. By adjusting parameters such as centrifugal force and temperature, efficient separation and purification of target components are realized. Centrifuges can be used for grinding, mixing, purification and separation processes to help optimize process conditions and improve product performance and quality.

Hot spot

Welcome to contact you by phone

Working hours(8:30-20:30)Enquiry hotline

+86 13255260239

Pay attention to customer service wechat

Working hours(8:30-20:30)