News Center

social responsibility

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

![]() Release date:2025.02.05

Release date:2025.02.05

![]() Page view:15

Page view:15

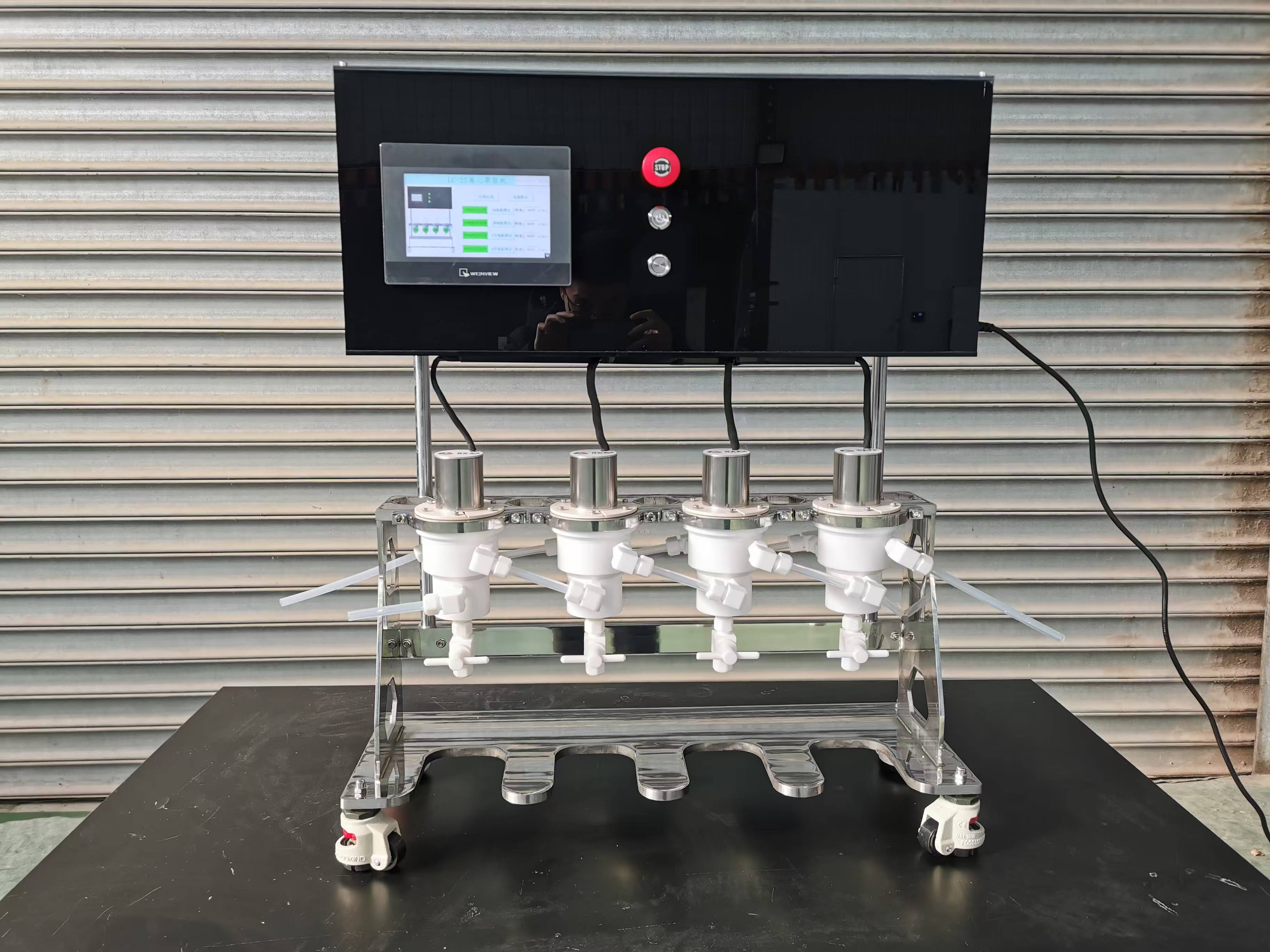

As a commonly used extraction equipment, extraction tank has a wide range of applications and special advantages in chemical production. The extraction tank is simple in structure and convenient in operation. It usually consists of multiple mixing and clarifying chambers arranged in a stepped manner.

In the working process, the extractant and the material liquid are fully mixed in the mixing chamber through the stirring device, so that the solute carries out mass transfer between the two phases. The mixture then enters the clarifying chamber, where it is stratified by gravity.

This structure makes the operation of the extraction tank relatively easy, does not require complex equipment and technology, and is suitable for large-scale industrial production. Its continuous production capacity is a significant advantage. In chemical production, many processes require the continuous processing of large quantities of materials.

The extraction tank can realize continuous feeding and discharging through the way of multi-stage series, and meet the continuous requirements of production.

For example, in the petrochemical industry, the use of extraction tank to deacid, dealkali and other pretreatment of petroleum distillates can ensure the stable operation of the production process and improve production efficiency.

The extraction tank also has good adaptability. It can handle materials with different properties, whether it is a liquid with high viscosity or a suspension containing solid particles, and can carry out an effective extraction operation to a certain extent.

In the pharmaceutical industry, the extraction tank is often used to extract pharmaceutical ingredients from the fermentation liquid, even if the fermentation liquid contains a certain amount of bacteria and impurities, the extraction tank can also be adjusted through reasonable operating parameters to achieve effective separation of pharmaceutical ingredients.

In addition, the investment cost of the extraction tank is relatively low. Compared with some high-end extraction equipment, the structure of the extraction tank is simple, and the manufacturing and installation cost is low.

For some companies with limited capital, extraction tanks are an affordable option while also meeting the basic needs of production.

However, the extraction tank also has some shortcomings, such as large footprint and relatively low separation efficiency. But with the continuous progress of technology, through the optimization of the extraction tank structure and the improvement of operating conditions, these problems are gradually being solved.

Extraction tank has become an indispensable extraction equipment in chemical production with its advantages of simple structure, continuous production, strong adaptability and low investment cost. In the future chemical production, the extraction tank will continue to play an important role, and achieve good development in continuous technological innovation.

Hot spot

Welcome to contact you by phone

Working hours(8:30-20:30)Enquiry hotline

+86 13255260239

Pay attention to customer service wechat

Working hours(8:30-20:30)