News Center

social responsibility

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

![]() Release date:2024.12.16

Release date:2024.12.16

![]() Page view:41

Page view:41

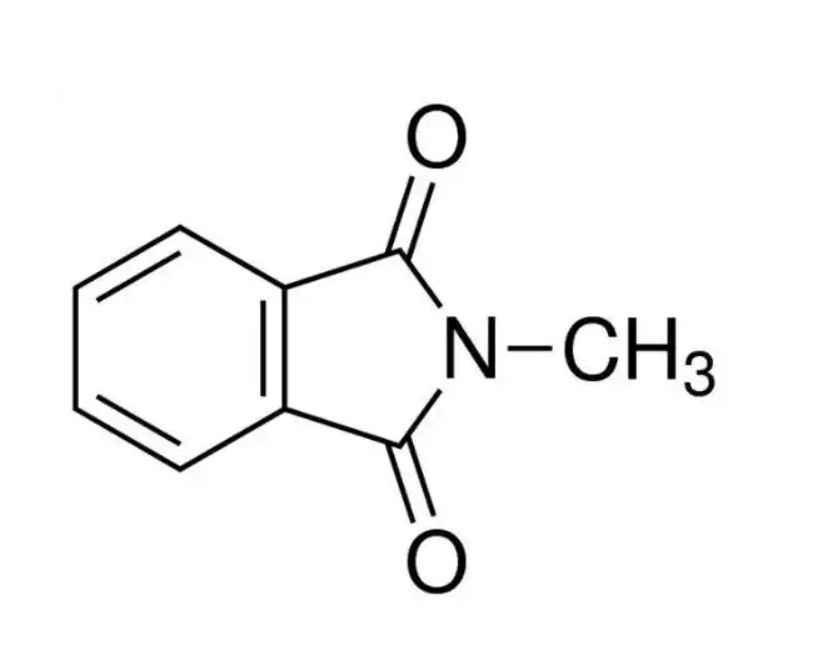

NMP (N-methylpyrrolidone) is a high-value chemical that has a wide range of applications in pharmaceutical, electronics, coatings and other industries. However, NMP wastewater treatment has been one of the challenges faced by these industries. The traditional treatment methods often have the problems of high energy consumption and low efficiency. With its unique separation mechanism and high efficiency, the combined extraction centrifugal extractor provides a new solution for NMP wastewater treatment.

1. Status and challenges of NMP wastewater treatment

NMP wastewater has high organic content, high COD, and certain toxicity, so it is difficult to treat. Traditional treatment methods such as distillation have the problems of high energy consumption and low efficiency. In addition, secondary pollution generated during the treatment process also has a serious impact on the environment.

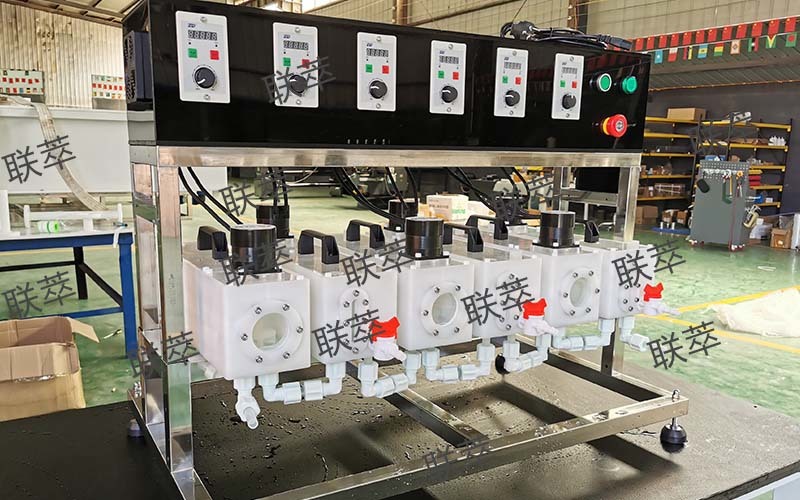

Second, the working principle and advantages of the combined extraction centrifugal extractor

The combined extraction centrifugal extractor uses the principle of centrifugal force to realize the rapid mixing and separation of two phases (extractant and wastewater) through a high-speed rotating drum. Its advantages are:

Efficient separation: Under the action of centrifugal force, the NMP in the wastewater can be quickly transferred to the extractant to achieve efficient separation.

Energy saving and environmental protection: Low energy consumption design, reduce energy consumption, while reducing wastewater discharge.

High degree of automation: integrated control system, remote monitoring and automatic adjustment, improve processing efficiency.

Third, the application of combined extraction centrifugal extractor in NMP wastewater treatment

In the NMP wastewater treatment, the combined extraction centrifugal extractor realizes the efficient and stable treatment process by selecting the appropriate extractant and adjusting the extraction conditions (such as comparison, flow rate, speed, etc.). The experimental results show that the treatment efficiency of the combined extraction centrifugal extractor is increased by nearly 40% and the production cost is reduced by more than 20% compared with the traditional treatment method. In addition, by optimizing the extraction process, the consumption of solvents and the discharge of wastewater are reduced, which effectively reduces the production cost and environmental burden.

The combined extraction centrifugal extractor has demonstrated significant innovation and economy in the treatment of NMP wastewater. In the future, with the continuous progress and optimization of technology, the combined extraction centrifugal extractor is expected to play a greater role in more fields and contribute to the sustainable development of chemical enterprises. At the same time, with the gradual application of new solvents such as green solvents and ionic liquids, NMP wastewater treatment will be more efficient and environmentally friendly.

Hot spot

Welcome to contact you by phone

Working hours(8:30-20:30)Enquiry hotline

+86 13255260239

Pay attention to customer service wechat

Working hours(8:30-20:30)