News Center

social responsibility

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

![]() Release date:2024.12.03

Release date:2024.12.03

![]() Page view:57

Page view:57

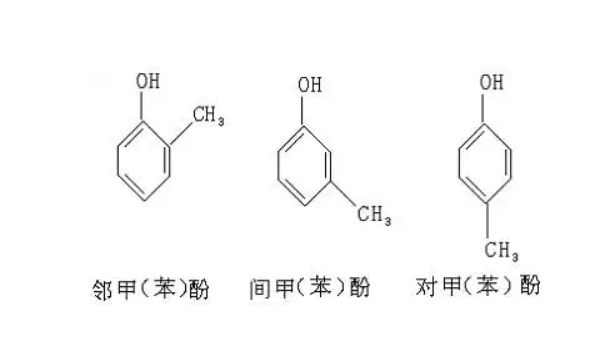

Cresol is an important chemical raw material, widely used in dyes, spices, and other fields. However, the separation of cresol isomers, such as m-cresol and p-cresol, has been a technical problem. Many methods, such as complex separation, extraction, melt crystallization and adsorption separation, have been used for the separation of cresol isomers. Among them, the extraction method has attracted much attention because of its simple operation and high separation efficiency. As a new and efficient liquid-liquid extraction separation equipment, the combined extraction centrifugal extractor has shown remarkable advantages in the separation of cresol isomers.

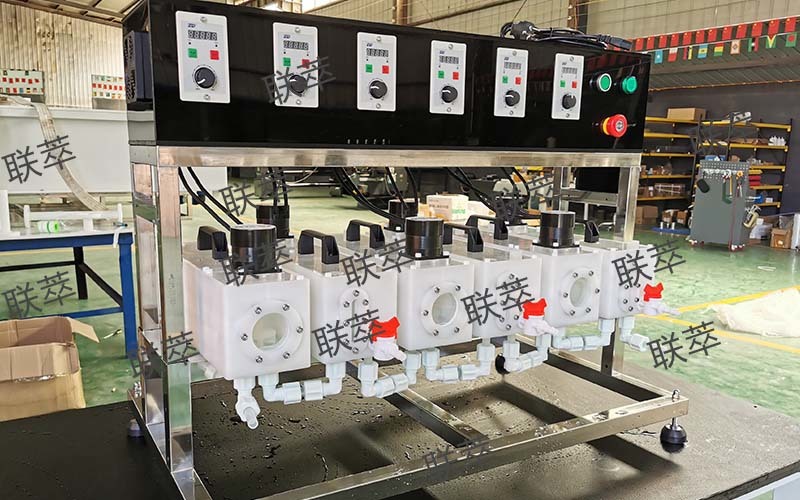

Working principle of combined extraction centrifugal extractor

The working principle of the combined extraction centrifugal extractor is based on the combined action of centrifugal force and shear force, so that two liquids with different densities and non-miscible can complete mixed mass transfer under the action of shear force generated by rotating drum or blade, and quickly separate under the action of centrifugal force. Through multistage operation, continuous countercurrent flow can be realized step by step to improve the separation efficiency.

Extraction and separation of cresol isomers

In the extraction and separation of cresol isomers, choosing the appropriate extractant is the key. The extractant should have a good solubility with one or more of the cresol isomers and a poor solubility with the other or more. By adjusting the extraction conditions (such as temperature, pH, etc.), the extraction effect can be further optimized.

In practice, the solution containing the isomer cresol and the extractant are injected into the centrifugal extractor in a certain proportion. Under the high-speed rotation of the drum, the two phases are quickly mixed and dispersed through the impeller to complete the mixed mass transfer process. The mixed liquid enters the rotating drum under the action of eddy disk, and under the action of centrifugal force, the two-phase liquid is quickly separated and discharged through different outlets to complete the two-phase separation process.

Extraction effect and optimization

The factors affecting the extraction effect include the selection of extractant, mixing strength, contact time, temperature and substance concentration difference. By optimizing these factors, the extraction efficiency can be significantly improved. For example, the extraction agent with selective solubility can improve the separation efficiency of the target cresol isomer. The mixing strength can be increased and the contact time can be prolonged by increasing the rotating speed and optimizing the blade design. By adjusting the temperature and pH value, the extraction conditions can be further optimized. Give a significant advantage.

In the separation of cresol isomers, the combined extraction centrifugal extractor has shown the characteristics of high efficiency, environmental protection and economy. By optimizing extraction conditions and selecting suitable extractants, the high efficiency separation and recovery of cresol isomers can be realized. The application of this technology will strongly promote the development and application of cresol isomer separation technology.

Hot spot

Welcome to contact you by phone

Working hours(8:30-20:30)Enquiry hotline

+86 13255260239

Pay attention to customer service wechat

Working hours(8:30-20:30)