News Center

social responsibility

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

![]() Release date:2024.11.25

Release date:2024.11.25

![]() Page view:60

Page view:60

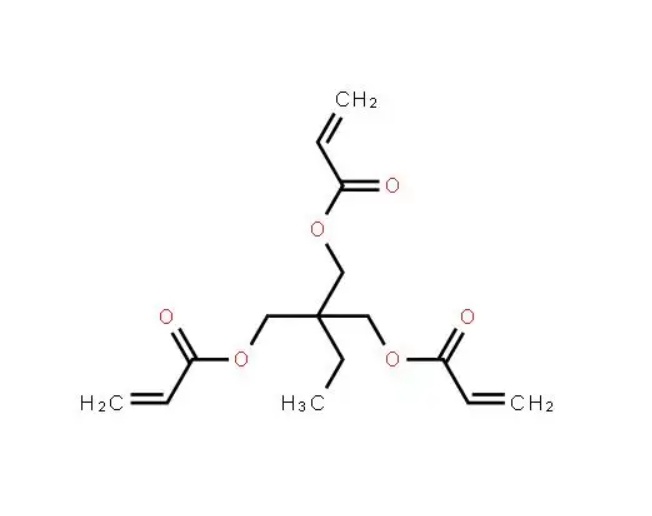

Trimethylol propane (TMP) is an important chemical raw material, widely used in resin, coatings, plastics and synthetic fibers. Its production process is complex and requires efficient separation and purification technology. As an advanced extraction equipment, the combined extraction centrifugal extractor provides a new solution for the separation and purification of TMP.

The production process of TMP mainly includes cross canizarro shrinkage and aldehyde hydrogenation reduction. Among them, the cross-canizarro condensation method is to produce TMP by the reaction of n-butanaldehyde and formaldehyde under the action of alkaline catalyst, but this method has more by-products and low product yield. The aldehyde hydrogenation reduction method has the advantages of high formaldehyde utilization rate, good product quality, simple purification and so on, and is currently the main production method used in Europe and America.

In the extraction process of TMP, the combined extraction centrifugal extractor utilizes the difference in solubility of different substances in the solvent to achieve efficient liquid-liquid extraction through the action of centrifugal force. Common extractants include organic solvents such as ethanol and methanol. After these solvents are mixed with TMP, the difference in partition coefficient enables the TMP to be efficiently separated from the reaction mixture.

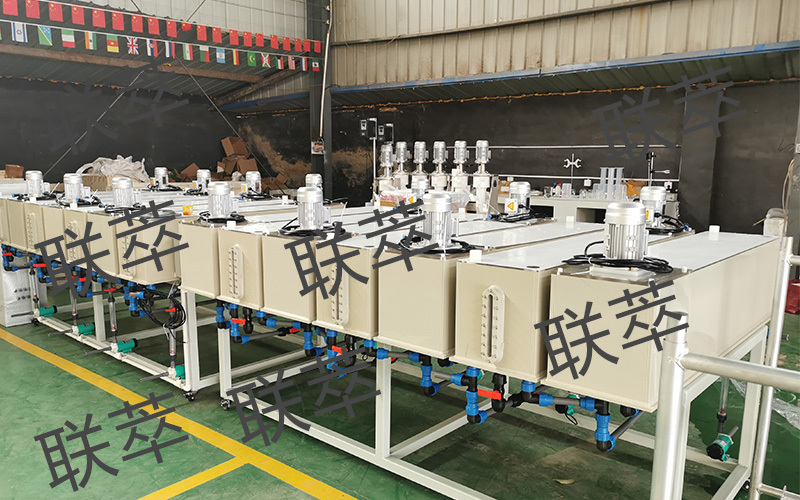

The advantages of the combined extraction centrifugal extractor are its efficient separation capacity and automated operation. By precisely controlling extraction temperature, pH, and extractant concentration, extraction results can be further optimized. The extraction temperature is generally controlled within the appropriate range to ensure the best separation effect. At the same time, multiple extractions are required during the extraction process, and adequate washing is carried out after each extraction to avoid residues.

In addition, the combined extraction centrifugal extractor also performs well in the purification process of TMP. With multistage countercurrent operation, the purity of TMP can be further improved to meet the needs of high quality products. At the same time, the equipment can also realize the recycling of extractants and reduce the production cost.

The combined extraction centrifugal extractor has shown good performance and wide application prospect in the extraction process of TMP. Its efficient separation capability, automated operation and precise control system make the extraction and purification of TMP simpler, more efficient and more reliable. In the future, with the continuous development of the chemical industry, the combined extraction centrifugal extractor will play a more important role in the production and purification of TMP.

Hot spot

Welcome to contact you by phone

Working hours(8:30-20:30)Enquiry hotline

+86 13255260239

Pay attention to customer service wechat

Working hours(8:30-20:30)