News Center

social responsibility

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

![]() Release date:2024.11.04

Release date:2024.11.04

![]() Page view:64

Page view:64

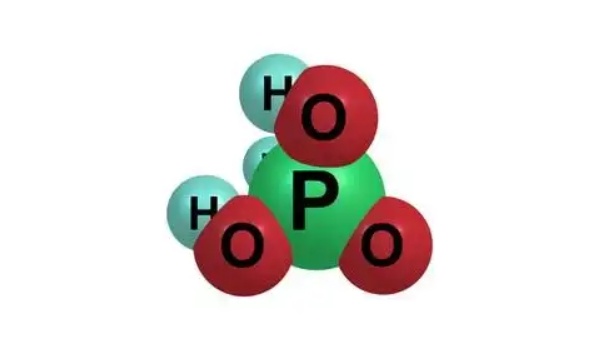

Phosphoric acid (H₃PO₄), as an indispensable chemical, has a wide range of applications due to its unique physico-chemical properties. However, phosphoric acid often contains impurities such as metal ions, the existence of these impurities will seriously affect its product quality and application effect. Therefore, phosphoric acid purification and impurity removal has become a crucial link. In this process, the combined extraction centrifugal extractor plays an irreplaceable role with its efficient and accurate separation ability.

Phosphoric acid purification and impurity removal extraction process (using a combined extraction centrifugal extractor) :

Raw material preparation: First, the phosphoric acid solution containing impurities is carefully pretreated, including the adjustment of pH value, temperature and other key parameters, in order to create an environment conducive to the extraction reaction, thereby optimizing the subsequent extraction effect.

Extractant selection: Carefully select extractants with strong selective extraction ability for metal ions and weak extraction ability for phosphoric acid itself, such as TBP (trioctylphosphine oxide). This step is key to ensuring that the extraction process is efficient and pure.

Extraction operation: the pre-treated phosphoric acid solution is evenly mixed with the selected extractant in a certain proportion, and then sent to the combined extraction centrifugal extractor. Under the strong action of centrifugal force, phosphoric acid and impurities are quickly and effectively separated, and the efficient removal of impurities is realized.

Phase separation and collection: Through the efficient phase separation mechanism built into the combined extraction centrifugal extractor, the mixed liquid is accurately separated into the organic phase rich in metal ions and the purified phosphoric acid solution. The two phases are then collected separately for subsequent processing.

Reverse extraction and recovery: The collected organic phase is reversed extraction treatment, using the appropriate reverse extraction agent to desorption metal ions from the organic phase, while recovering the extractant for recycling. This process not only maximizes the use of resources, but also reduces production costs.

Purification and purification: Further purification and purification of the phosphoric acid solution after extraction, such as filtration, ion exchange, etc., to completely remove residual impurities and trace metal ions, and further improve the purity of phosphoric acid. In the end, high purity phosphoric acid products are obtained to meet the needs of various industries for high-quality phosphoric acid. The combined extraction centrifugal extractor plays a vital role in the process of phosphoric acid purification and impurity removal.

Hot spot

Welcome to contact you by phone

Working hours(8:30-20:30)Enquiry hotline

+86 13255260239

Pay attention to customer service wechat

Working hours(8:30-20:30)