News Center

social responsibility

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

![]() Release date:2024.10.14

Release date:2024.10.14

![]() Page view:117

Page view:117

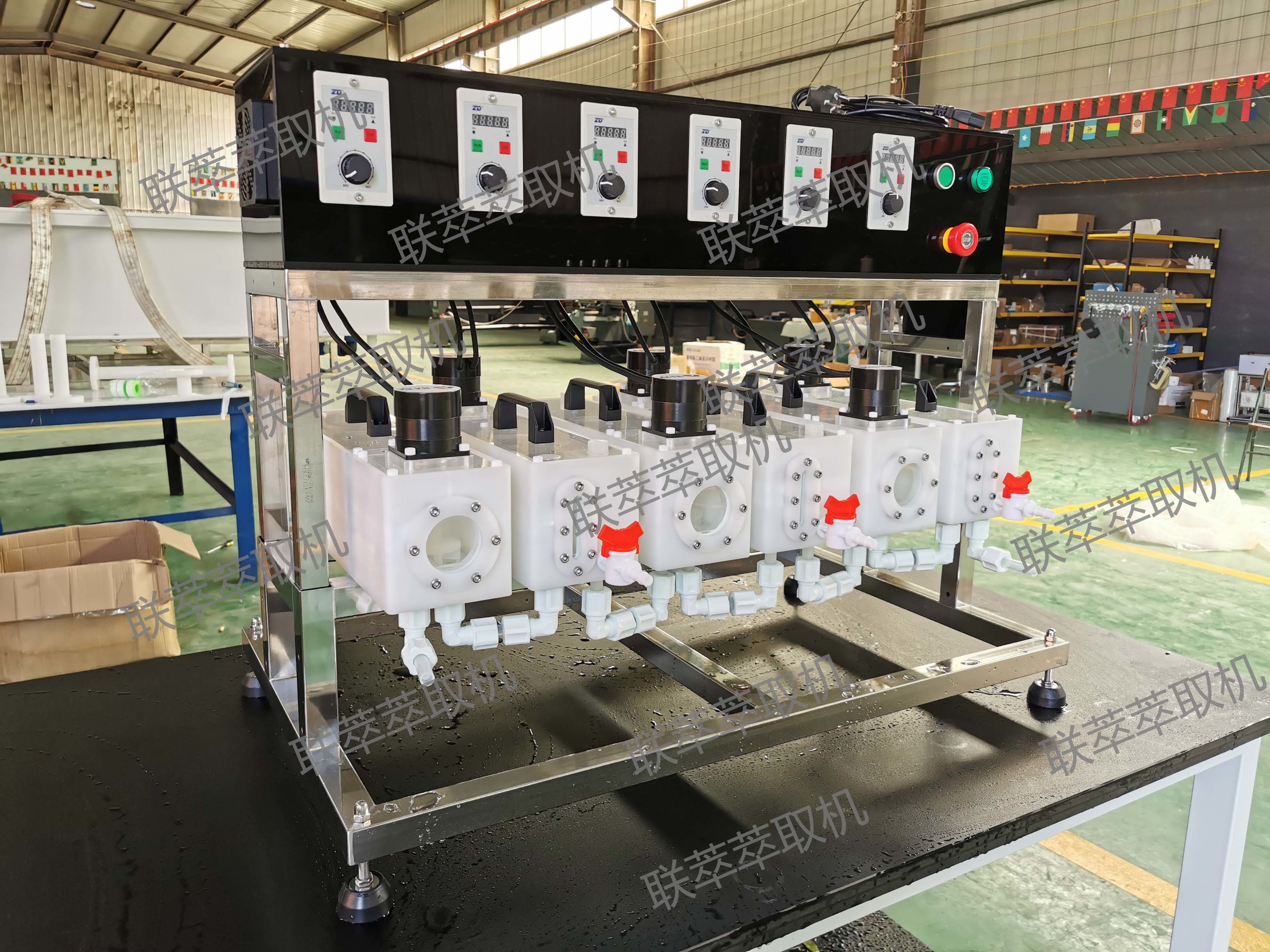

In the pursuit of high efficiency, energy saving and environmental protection of modern chemical separation technology, molecular distillation stands out with its unique advantages, and as an advanced extraction equipment, the combination of the two under specific process conditions has opened up a new path for the separation and purification of complex systems. The following is an analysis of the characteristics of molecular distillation, cleverly incorporating the advantages of a combined extraction centrifugal extractor.

1. Low temperature separation to protect sensitive components

Molecular distillation is carried out under extremely high vacuum conditions, so that the separation temperature is much lower than the conventional boiling point of the material, effectively avoiding the problem of thermal decomposition of the separated material due to high temperature. When combined with a combined extractor, the extraction process can also be carried out under mild conditions, further protecting temperature-sensitive components and ensuring product integrity and high purity.

2. High vacuum, inhibit oxidation

The high vacuum in the system not only reduces the distillation temperature, but also significantly reduces the risk of oxidative decomposition of peroxides. The combined extraction centrifugal extractor reduces the entry of impurities into the distillation system through its efficient separation capacity during the extraction stage, thus maintaining the high vacuum environment of the molecular distillation process, further improving the separation effect and product quality.

3. Short heat, efficient mass transfer

During the molecular distillation process, the liquid film thickness is extremely thin (about 0.25~0.5mm), which makes the heating time extremely short, usually a few seconds to tens of seconds, effectively reducing the degradation of heat-sensitive substances. Through its unique rotor system design, the combined extraction centrifugal extractor realizes the efficient mixing and rapid mass transfer of materials, which provides high-quality feed for the subsequent molecular distillation process and ensures the high efficiency of the entire separation process.

4. High separation, improve efficiency

Molecular distillation has a higher relative volatility than conventional distillation, so it can achieve higher separation efficiency and purity. As a pre-treatment step, the combined extraction centrifugal extractor can remove some impurities in advance and reduce the burden of molecular distillation. The synergistic effect of the two makes the whole separation process more efficient and accurate.

5. Irreversible evaporation to ensure purity

The distance between the evaporating surface and the condensing surface in the molecular still is very short, which is less than the mean free path of the light molecules, so that the evaporated light molecules almost reach the condensing surface without collision, and the irreversibility of evaporation is realized. Through its precise extraction control, the combined extraction centrifugal extractor further reduces the backmixing phenomenon and ensures the high purity of the final product.

6. No boiling bubble, stable process

In the process of molecular distillation, the liquid evaporates freely in the form of a thin film at low pressure without boiling and bubbling, which ensures the stability and continuity of the distillation process. The combined extraction centrifugal extractor is also known for its stable, controllable operation, and the combination of the two makes the entire separation process more stable and reliable.

7. Clean environmental protection, green production

Molecular distillation and combined extraction centrifugal extractor are pure physical separation processes, do not involve chemical changes and the generation of harmful substances, in line with the green production concept. The synergy of the two processes not only improves the separation efficiency and product quality, but also promotes the sustainable development of the chemical industry.

The combination of combined extraction centrifugal extractor and molecular distillation technology has brought more efficient, lower temperature and cleaner solutions to the field of chemical separation, and is an important force to promote technological progress and green transformation of the industry.

Hot spot

Welcome to contact you by phone

Working hours(8:30-20:30)Enquiry hotline

+86 13255260239

Pay attention to customer service wechat

Working hours(8:30-20:30)