News Center

social responsibility

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

![]() Release date:2024.10.08

Release date:2024.10.08

![]() Page view:73

Page view:73

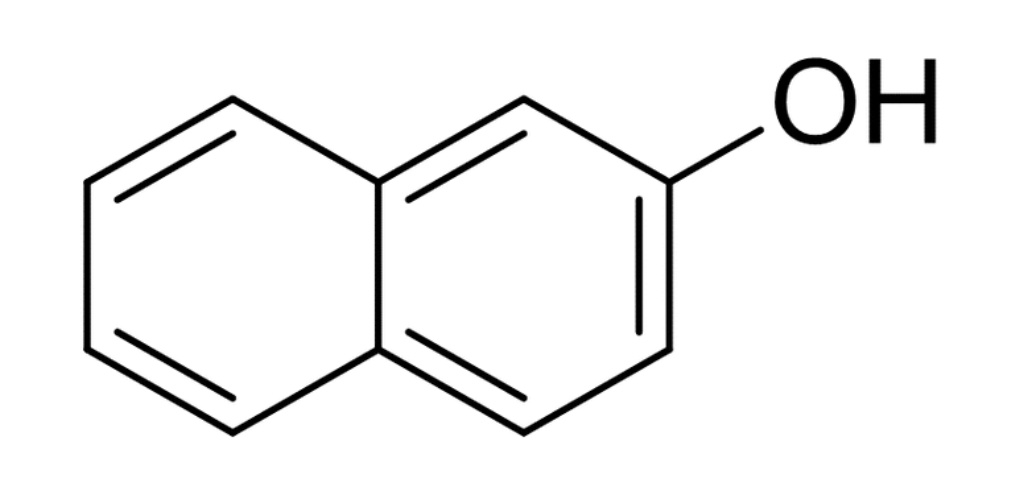

2-naphthol is a widely used fine chemical intermediate. In the industrial production process, refined naphthol is usually used as raw material and prepared by sulfonation, hydrolysis, neutralization, alkali melting, acidification, refining and other processes. According to statistics, the production of 2-naphthol per ton produces about 10 tons of wastewater, which has high salt content, high toxicity, dark color and high COD concentration, and has a big pollution hazard to the environment. At present, the treatment technologies for this kind of wastewater mainly include chemical method, resin adsorption method, solvent extraction method and biochemical method.

Through its high-speed rotation and powerful centrifugal force, the combined extraction centrifugal extractor realizes efficient substance separation, making the extraction process more rapid and accurate, and significantly improving the removal rate of pollutants in wastewater.

The low power consumption design and high solvent utilization of the combined extractor make the equipment not only efficient, but also more environmentally friendly. By multistage countercurrent centrifugal extraction, COD concentration in wastewater can be greatly reduced and environmental pollution can be reduced.

The design of the equipment fully considers the optimization of the input and use cost, the operating cost is low, and the economic benefit is remarkable. In addition, the footprint is small, the operation and maintenance is convenient, and the operation and maintenance costs of the enterprise are greatly reduced.

The combined extraction centrifugal extractor can establish the phase balance in a short time to ensure the efficient and stable operation of the entire extraction process. Through multistage countercurrent operation, the separation efficiency and processing capacity are further improved.

In addition to its excellent performance in the treatment of 2-naphthol wastewater, the combined extraction centrifugal extractor also shows a wide range of application potential in the treatment of a variety of other industrial wastewater:

The combined extraction centrifugal extractor can efficiently separate the heavy metal ions in the wastewater, reduce its concentration, and ensure the wastewater discharge standards.

In the process of chemical production, it is often necessary to recover organic solvents in wastewater. Combined extraction centrifugal extractor can recover organic solvent efficiently and reduce resource waste through high efficiency centrifugal separation technology.

For high-salt wastewater, the combined extraction centrifugal extractor can effectively separate and treat the high-salt components in the wastewater through efficient extraction and separation, and reduce the treatment cost.

The application of combined extraction centrifugal extractor not only improves the efficiency and effect of industrial wastewater treatment, but also promotes the green development of the entire environmental protection wastewater treatment industry. Its characteristics of high efficiency, energy saving and environmental protection make it an ideal choice for industrial wastewater treatment and provide strong support for the sustainable development of the industry.

Hot spot

Welcome to contact you by phone

Working hours(8:30-20:30)Enquiry hotline

+86 13255260239

Pay attention to customer service wechat

Working hours(8:30-20:30)