News Center

social responsibility

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

![]() Release date:2024.09.30

Release date:2024.09.30

![]() Page view:97

Page view:97

Polyphenylene sulfide (PPS) is a new type of special engineering plastic, known as "the world's sixth largest engineering plastic", is also one of the eight major aerospace materials. With its excellent heat resistance, corrosion resistance, flame retardant, electrical insulation and processing properties, PPS has been widely used in automotive, electronics, aerospace and precision instrumentation and other industrial sectors. However, in the production process of PPS, sodium chloride, lithium chloride and a small amount of oligomers and solutions containing N-methylpyrrolidone (NMP) are produced, and these by-products are highly valuable for recovery. The recovery rate of NMP can be greatly improved to more than 99.6% by using the combined extraction centrifugal extractor.

** 1. Application of combined extraction centrifugal extractor in PPS production **

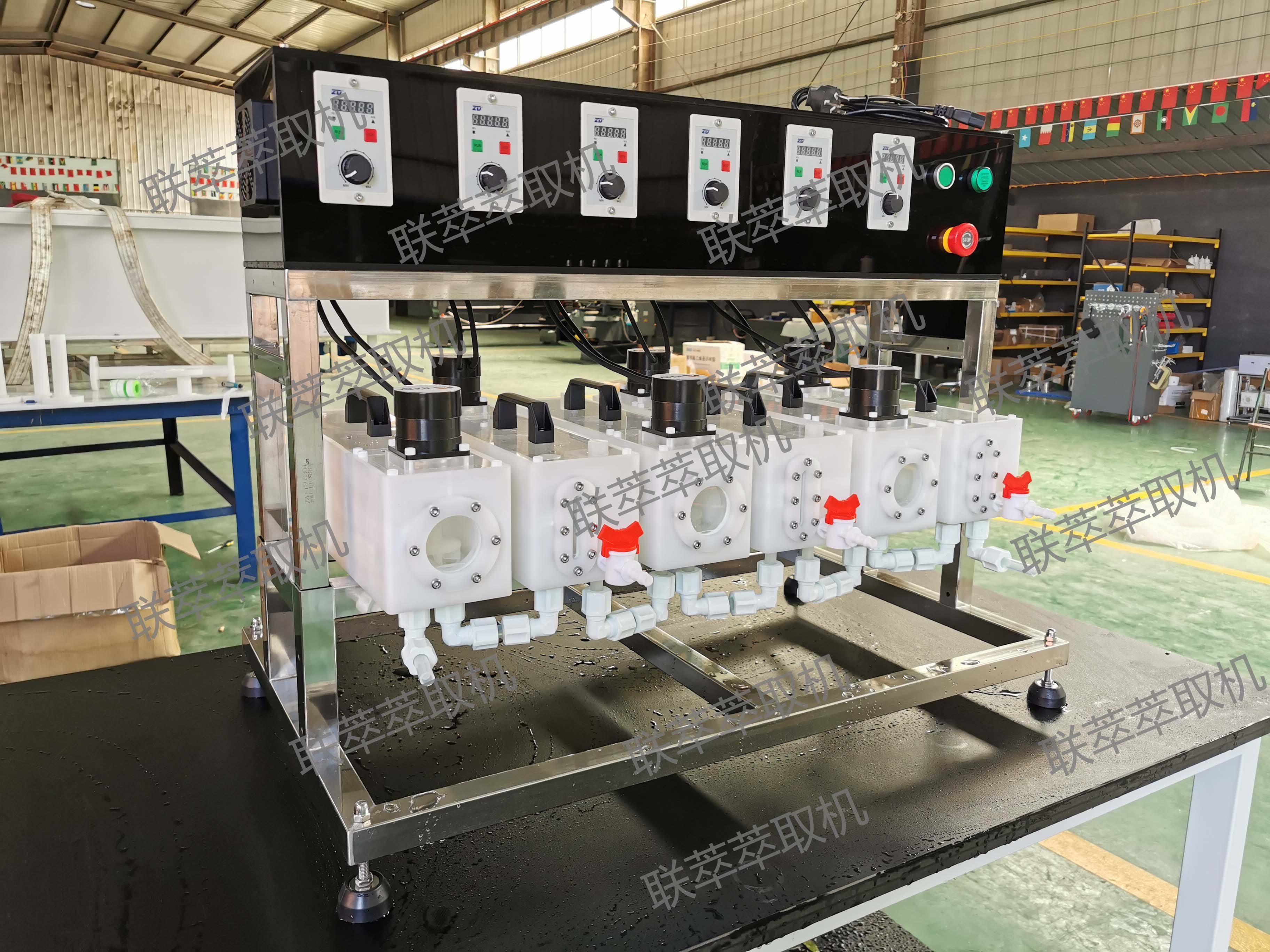

In the production process of polyphenylene sulfide, trichloromethane is often used as extractant, and NMP is recovered by series countercurrent extraction system consisting of 5-8 suspended centrifugal extraction units. The combined extraction centrifugal extractor, with its excellent technical performance, plays a vital role in this process. The efficient separation capability and stable operation performance of the equipment make the recovery rate of NMP reach more than 99.6%, which greatly improves the resource utilization rate and reduces the production cost.

The combined extraction centrifugal extractor is equipped with CIP online cleaning mechanism, which can realize automatic online cleaning and rinsing. In the case of not disassembling the machine, the equipment can efficiently and quickly remove the solid deposited inside the drum, ensuring the continuous and efficient operation of the equipment. This technical advantage not only reduces maintenance costs, but also reduces equipment downtime and improves production efficiency.

** II. Multi-functional application of combined extraction centrifugal extractor **

In addition to its application in PPS production, the combined extraction centrifugal extractor also shows a wide range of potential applications in other separation and extraction processes in the field of plastics. Here are some key application areas:

1. Extraction and separation of plastic additives ** : In the plastic production process, the separation and extraction of additives is an important link. The combined extraction centrifugal extractor can effectively extract and separate a variety of additives to improve product quality and performance through its efficient separation ability.

2. ** Waste liquid recycling and resource reuse ** : The waste liquid generated in the production process of plastics often contains a large number of valuable chemicals. Through the application of the combined extraction centrifugal extractor, these substances can be effectively recycled, reduce waste emissions, and promote the recycling of resources.

3. ** Versatility and high efficiency ** : The design of the combined extraction centrifugal extractor fully considers the versatility and high efficiency, so that it can adapt to a variety of complex chemical and environmental protection processes. It can not only handle high concentrations, high viscosity and toxic and harmful substances, but also maintain stable performance under different operating conditions.

** Third, technical advantages to help the green development of plastics industry **

The application of the combined extraction centrifugal extractor not only improves the resource utilization efficiency in the plastic production process, but also promotes the green development of the entire industry. The following are its key technical advantages:

1. ** Efficient separation performance ** : Through its high-speed rotation and strong centrifugal force, the combined extraction centrifugal extractor can achieve efficient substance separation, making the extraction process more rapid and accurate.

2. ** Innovative structural design ** : The equipment adopts upper suspension design and multi-level series countercurrent operation, which greatly improves the separation efficiency and product purity, and is suitable for complex chemical separation and extraction processes.

3. ** Green ** : Low power consumption design and recycling of extractants make the combined extraction centrifugal extractor not only efficient, but also more environmentally friendly. The extractant can be recycled many times and the waste of resources is reduced.

4. Automation and intelligence: CIP online cleaning mechanism and automatic control system ensure the efficient operation and simple maintenance of the equipment, which greatly reduces the operating costs of the enterprise.

Through the application of the combined extraction centrifugal extractor, a number of production processes in the field of plastics have been significantly optimized, and production efficiency and product quality have been greatly improved. Its characteristics of high efficiency, automation and environmental protection make it an ideal choice for the plastics industry and provide strong support for the sustainable development of the industry. The combined extraction centrifugal extractor not only performs well in the production of polyphenylene sulfide, but also shows extensive application potential in the extraction separation of other plastic additives and waste liquid recovery.

Hot spot

Welcome to contact you by phone

Working hours(8:30-20:30)Enquiry hotline

+86 13255260239

Pay attention to customer service wechat

Working hours(8:30-20:30)