News Center

social responsibility

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

![]() Release date:2024.09.18

Release date:2024.09.18

![]() Page view:88

Page view:88

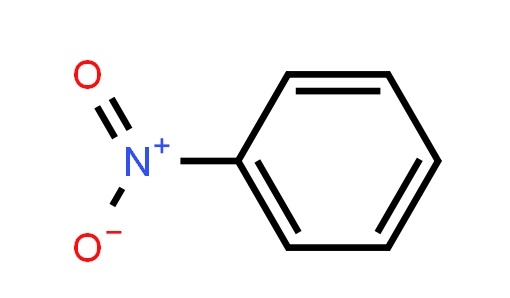

In the production of nitrobenzene, the organic phase product obtained after the nitration reaction usually contains impurities such as nitric acid, sulfuric acid, and nitrophenol, which are by-products of the nitration reaction. These impurities not only affect product quality but also cause corrosion to subsequent equipment and pipelines, posing safety hazards. Therefore, they must be removed.

The Shandong Liancuo High-Efficiency Centrifugal Extractor has successfully solved the technical problems of low separation efficiency and large wastewater generation in traditional kettles and tanks by forming a countercurrent extraction system through multi-stage cascading. The serial system of the Liancuo high-efficiency centrifugal extractor has excellent washing effects, which can reduce the use of washing liquid. The equipment operates in a closed manner and continuously, with high automation and small footprint. Therefore, it is widely used in the production of chemical raw materials and intermediates.

Compared with traditional extraction tanks, extractors, and reactors, the Liancuo centrifugal solvent extraction has a series of advantages, including high efficiency, low retention, continuous operation, equipment closure, and high automation. This high-efficiency centrifugal extraction technology can not only effectively separate impurities but also produce high-quality products, providing a reliable solution for the production of nitrobenzene.

Hot spot

Welcome to contact you by phone

Working hours(8:30-20:30)Enquiry hotline

+86 13255260239

Pay attention to customer service wechat

Working hours(8:30-20:30)