News Center

social responsibility

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

hot line: +86 13255260239

mailbox: yaodongwang65@gmail.com

address: Room 702A11, Building 1, Jinan Science and Technology Innovation Center, Guangdong Pu Science and Technology, 500 meters southeast of the intersection of Kejia Road and Chunxiu Road, High-tech Zone, Jinan City, Shandong Province

![]() Release date:2024.09.14

Release date:2024.09.14

![]() Page view:63

Page view:63

The advanced technology and equipment such as automatic centrifuge are widely involved in the engineering application of modern medicine, Chinese medicine, intermediates and biological fields.

In the pharmaceutical industry, the production and preparation process of drugs covers many links such as chemical reaction, physical treatment and biological fermentation. The production operation unit involves important steps such as reaction, extraction, decolorization, filtration, crystallization and drying.

The filter washing and drying machine (often referred to as the Nucor filter, 2-in-1 or 3-in-1 equipment) combines the multiple functions of filtration, washing and drying and is widely used in the pharmaceutical industry. Its main features include:

Multi-functional integration: automatic feeding, pulping, washing, filtration and drying in one machine, greatly improving production efficiency.

Flexible operation: repeated pulping and filtration according to process requirements.

Advanced cleaning and sterilization: CIP (in situ cleaning) and SIP (in situ sterilization) functions are supported.

Automation control: the whole process of automatic program control, approaching unmanned intelligence.

Applicable environment: The equipment is airtight, suitable for handling flammable, explosive, toxic and harmful or sensitive materials.

Convenient maintenance: A variety of cylinder structures, spindle sealing and filter media can be selected for easy operation and maintenance.

Comply with GMP (Good Manufacturing Practice) and ESH (Environment, Safety and Health) management requirements.

The application of traditional filter washing equipment such as plate and frame filter presses and centrifuges in the pharmaceutical industry has gradually become insufficient, and MY three-in-one filter has successfully filled this gap with its unique structure and technical advantages.

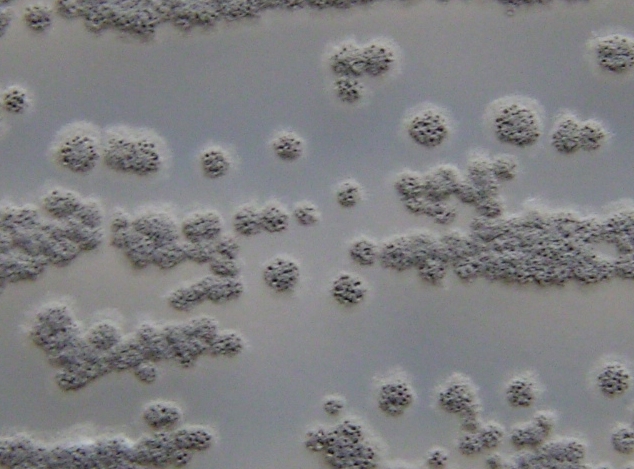

An antibiotic produced by Streptomyces lincoensis, which has strong antibacterial properties and is widely used in the treatment of clinical infectious diseases. The production process includes fermentation solution pretreatment, filtration, solvent extraction, crystallization, washing and drying. MY series filter washing and drying machine can effectively remove the isomer Lincomycin B in crystallized crude products through multiple pulping washing, reducing the washing time, reducing the amount of washing liquid, significantly improving the washing effect, and winning unanimous praise from applied pharmaceutical companies.

A high-quality antioxidant, widely used in health foods, antioxidants, food additives, colorants and feed additives. The production process includes marigold flower harvesting, enzymatic hydrolysis, dehydration, drying, granulation, low temperature leaching, lutein extract preparation and packaging. In the application of lutein extract separation section, the filter washing and drying machine realizes high-precision washing and filtration, improves the purity of the product and meets the production requirements by relying on its multi-layer stainless steel filter medium. At the same time, the equipment has the advantages of sealing and explosion-proof, high automation and easy operation and maintenance, and is widely used in animal extracts, raw materials, pharmaceutical intermediates and other plant extraction fields.

Hot spot

Welcome to contact you by phone

Working hours(8:30-20:30)Enquiry hotline

+86 13255260239

Pay attention to customer service wechat

Working hours(8:30-20:30)